Flamefast products

Mardon - Bulk Waste Extractor

The Mardon PL16 Dust Extractor has been designed specifically for use with machines which produce bulk waste such as Planers and Wood Lathes in line with HSG258 Guidelines. However it may be used for other similar applications and offers the designer a realistic alternative to a Centralised Ducted System. The Mardon PL16 has exceptionally low noise characteristics for use within the classroom and is designed for use with coarse dusts, hence the large collection bin capacity and the comparatively low footprint area of the machine. Warm air is returned to the classroom being sympathetic to environmental issues.

Workshop Equipment- Metal

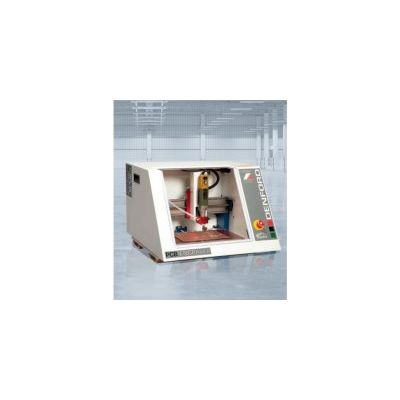

Engraver

The PCB Engraver is ideal for cutting and engraving a range of resistant materials, including copper board, plastic and acrylic, it comes supplied with operating software incorporating Gerber and DXF import facilities. CAD, CAM and/or PCB design software, such as the QuickCAM 2D Design, will be required in order to make the files required for machining (CNC G-Code or Gerber). N.B. To allow optimum performance of the floating head, dust extraction is essential. The FLA-PCB Engraving machine features the latest ‘Floating Head’ technology. The floating head allows manufacture of PCB’s, and engraving of uneven surfaces. The PCB Engraver is also ideal for batch manufacture of PCB boards.

Workshop Equipment- Wood

Circular Saw Bench

Industrial quality circular saw, primarily designed for rip work, compact in size but of very robust construction. Based around an all welded steel base with a heavy, finely ground, all cast iron table and amply powered by a mechanically braked induction motor. A small sliding table of cast iron running on an adjustable bearing system, complete with a mitre fence and a sliding support arm is a standard fitting, ideal for small boards or panels. This folds down out of the way if not required, saving space in the workshop.

Hot Metal & Foundry - Brazing

Castolin dyomix - Portable Brazing System

The Castolin dyomix® OHM 2.4 is an easy to use portable brazing system that is ideal for professionals using a flame torch in their daily work or teachings. The system outputs a clean high-performance fuel from the oxygen and hydrogen naturally present in water, with no storage requirements.

Flamefast - Brazing Hearth System

The DS400 is supplied with an easy-to-use single valve controlled RF80 torch which allows one-hand opertion. Supplied with a solid refractory hearth with robust side and rear heat shields, the DS400 complies with British Gas standards and is a fully failsafe system. All sequences are visually displayed using neon indicators. On start-up the gas train, hoses and torches are tested for escaping gas. Leaks from any component will result in a continuously illuminated red neon and the main flow of gas will be prevented from entering the system.

Hot Metal & Foundry - Torches

Flamefast - Gas Torches

A range of single hand operated soldering and brazing torches developed for fine jewellery and heavy brazing. The Flamefast RF range of Gas/Air torches is constructed from nickel plated brass with a heat resistant steel burner head ensuring a long and reliable service. Two torches are available, the RF80 which is designed for heavy brazing and the RF10 which is smaller in size with a heat output ideal for fine jewellery. Permanent pilot flame, parking hook, screwed connections for flexible hoses and work piece cooling by rapid air blast plus a choice of models for natural or bottled gas, make the RF range of gas/air torches simple and convenient to use. Built-in balance and position of controls enables effortless single handed operation. Instantaneous adjustment of flame size, shape and intensity over the full range is achieved by a single rotary control valve and air throttle button. The torches are designed to operate only with the Flamefast 9MS8 whisper quiet blower fan.

Flamefast - Gas Torches

Developed to give a wide range of flames at the turn of a valve, these torches are ideal for brazing, soldering, metal melting, heat treatment, glass, lead and tinning work. The Flamefast T range of Gas/Air torches are constructed from nickel plated brass with a heat resistant steel burner head ensuring a long and reliable service. Two torches are available, the T4 which is designed for heavy brazing and the T2 which is smaller in size with a heat output for more delicate work. The torches are designed to work with an air supply pressure regulated at 4 lbs/in2 - 270 mbar.

Hot Metal & Foundry - Casting

Flamefast - Low Temperature Casting Units

Flamefast have always been at the forefront of Hot Metal equipment design for education. The Low-Temperature Casting System has been designed to create unique links between Design & Technology and other curriculum areas such as ICT and Art. At the same time it offers a cost-effective and safe method for casting and moulding lessons.

Hot Metal & Foundry - Forging

Flamefast - Ceramic Chip Forge

The DS430A is a Ceramic Chip Forge, the design of which is based on Flamefast`s many years of experience designing safe, quiet running gas forges and brazing hearths. The forge has a single phase whisper quiet integral fan to provide the air supply and takes only 15 minutes to reach a working temperature. It can reach a temperature of 1,500°C. It has a 340mm diameter working area and can work up to 50mm steel bar. The ceramic chip technology minimises surface scale formation. The forge has a single phase whisper quiet integral fan to provide the air supply with fail safe auto ignition for the gas supply. The forge has a cast iron base for a long maintenance free life. As with all Flamefast equipment, the DS430A Chip Forge is covered by the Flamefast unconditional 2-year warranty.

Hot Metal & Foundry - Crucible Furnaces

Flamefast - Safety Tilt Crucible Furnace

This easy to use furnace is ideal for fast melts of aluminium. The unit incorporates the Flamefast tilt and pour principle, which ensures safer metal pouring and extended crucible life. The Crucible Furnace is usually placed on a Flamefast Raised Sand Tray (1200 (L) x 800 (W) x 300mm (H)) which removes the need for a casting pit. The sand tray raises the crucible to a more convenient working height and means that only protective leggings are needed rather than protective footwear. The burner has a piezo igniter and is fitted with flame failure protection. The essential simplicity of the CM450 means that the unit requires minimum maintenance.