- Home

- Companies

- Hasler Group

- Products

Hasler Group products

Solutions - Agitation

Hasler - Model LUMPP - Side-Entry Mixers

LUMPPs side-entry mixers are designed and manufacturer to be installed through the side of tanks. This range of mixers has been specially designed to be fitted closed to the bottom of the tank. These mixers cover most of the needs in various storage tanks where homogenization is required. These mixers are designed to be installed on DN flanges and are able to handle a density up to 1,100 kg/m3 and a viscosity up to 500 cps.

Hasler - Model LUMPP - Customized Mixers

LUMPP’s customized mixers are designed and manufactured to meet the specific needs of the customer. Whatever process, installation, energy, space constraints the customer has, LUMPP®’s customized mixer will comply with it. Lumpp has been involved for many years in numerous corrosive applications. Lump has therefore developed a specific knowledge in handling, forming and fabricating reactive material such as titanium, tantalum, zirconium.The mixers can be manufactured with all these reactive metals.

Hasler - Model LUMPP - Top Entry Mixers with Sealing

LUMPP’s top-entry mixers with sealing are designed and manufactured to be installed in a closed tank, up to 15 barG with an inside temperature up to 200°C. This range of mixers has been specially designed DIN reactors and are able to handle a density up to 1,300 kg/m3 and a viscosity up to 2,000 cps.

Hasler - Model LUMPP - Top Entry Mixers without Sealing

LUMPP’s top-entry mixers without sealing are designed and manufactured to be installed in an open tank with atmospheric pressure and an inside temperature up to 100°C. This range of mixers has been specially designed to cover most of the usual needs in terms of standard agitation and to be able to handle a density up to 1,200 kg/m3 and a viscosity up to 500 cps.

Hasler - Model LUMPP - Impellers

LUMPP’s impellers have been designed for years to cope with all the process problems our customers are facing. Lumpp’s impellers can be found in every single process depending on the function the process requires. Different types of Lumpp’s impellers can be found in one tank to cope with different process characteristics.

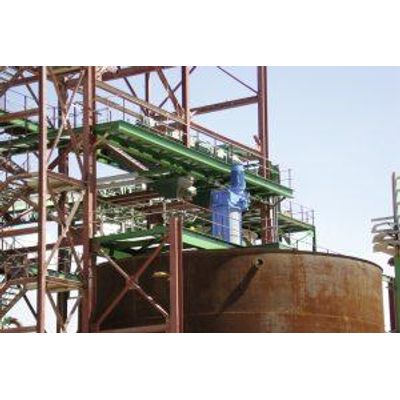

Hasler - Model LUMPP - Heavy-Duty Mixers

LUMPP‘s heavy-duty mixers are designed and manufactured to handle very demanding processes in very large tanks. Heavy-duty mixers are designed to handle high loads and high torque. Most heavy duty LUMPP mixers show impressive features.

Hasler - Model LA - Impellers

Propeller dedicated storage, with low encroachment, low surface area, and few inclinations, suitable for slight agitation. Can offer high shear. Ideal for the preparation of lime milk, for example. LA type of propeller decreases the hanging tows.

Hasler - Model LB - Impellers

Propeller type for waste water treatment applications like, floculation, reagent preparation,and neutralization. This propeller is characterized by a large developped area, for average to severe agitation fited to many processes due to its hydraulical characteristics.

Hasler - Model LC - Impellers

Propeller with average-size with axial flowl mailnly axial. Often proposed for ore attack reactors (leaching), and for suspending solids (concentration