- Home

- Companies

- Hasler Group

- Products

Hasler Group products

Solutions - Dosing

Hasler - Model GRAVIT 2 - High-precision Universal Weigh Belt Feeder for Granular Materials

The GRAVIT 2 is a high-precision universal weigh belt feeder for granular materials designed to optimize user experience and maintenance operations. The GRAVIT 2 dosing solution is the latest generation of the GRAVIT belt feeder designed by our experts. It combines performance, accessibility, modularity, and safety to meet the demands of continuous industrial processes (24/7).

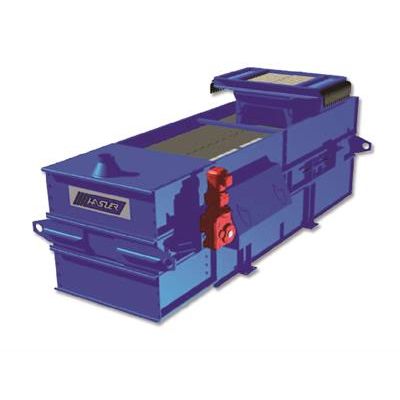

Hasler - Model GI GRAVIT - Weigh Belt Feeder for Granular Materials

The material flows from the storage silo through the inlet onto the belt and is conveyed to the weigh bridge. Taking into account the distance between the weigh bridge and the discharge point, the flowrate is calculated according to the load at the discharge point and the belt speed. The flow rate is kept constant by the SCM 2 controller modifying the belt speed according to the load and the setpoint applied.

Hasler - Model MAMMUTHUS - Apron Extractor Weigh Feeder

The MAMMUTHUS apron extractor weigh feeder combines the robustness of a metal apron extractor feeder with the functionality of a belt feeder. Its transport speed is regulated according to the material load, ensuring precise, constant metering. The MAMMUTHUS is a versatile industrial feeder system that is entirely enclosed for continuous process. It combines a discharge feeder with a belt feeder in a single piece of equipment, minimising footprint and maintenance.

Hasler - Model MAMMUTHUS 2000 - Apron Extractor Weigh Feeder

The MAMMUTHUS 2000 industrial extractor weigh feeder combines the functions of a metal apron extractor and a belt feeder. Specially designed for very high flow rates, it is ideal for extracting, dosing and transporting materials with high particle size and humidity such as clay, gypsum and limestone. It ensures a stable, accurate flow rate of different materials. With an accuracy of ±1%, this solution is essential to guarantee high-precision industrial dosing within continuous processes.

Hasler - Model MAMMUTHUS Clinker - Apron Extractor Weigh Feeder

The MAMMUTHUS Clinker extractor weigh feeder offers the robustness of a metal apron extractor with the precision of a belt feeder. This industrial gravimetric dosing system for continuous processes is specially designed to transport very hot and abrasive products such as clinker, making it possible to meet the requirements of heavy industries such as cement plants. The mechanical design of the MAMMUTHUS Clinker provides accurate, constant dosing of the transported materials. It combines an extractor and a weigh feeder in a single machine, minimising the maintenance and footprint of the equipment. With a margin of error of ±1%, the system is positioned as essential equipment for industrial dosing in continuous processes (24/7).

Hasler - Smart Apron Scale (SAS)

The SAS belt scale represents a continuous weighing solution specifically designed for steel or bucket conveyors. This industrial dosing device offers real-time measurement of bulk material flow conveyed on a metal apron, suitable for environments with high temperatures of up to 150°C. It enables a dynamic tare function without needing to empty the upstream silo beforehand. This belt scale automatically detects belt rotation, improving dosing efficiency using its speed detection wheel. Furthermore, it ensures accurate totalisation of cumulative weight, enabling monitoring and accurate regulation of material flows.

Hasler - Smart Belt Scale (SBS)

The Smart Belt Scale is a conveyor belt scale specially designed for rugged outdoor environments such as quarries, gravel processing and mining. It is also well suited for any manufacturing process using conveyor belts, including: cement, fertilizer, chemical, tobacco, agro-food, etc… It is designed for easy installation which can be done by the customer’s own maintenance staff.

Hasler - Model LBS - Large Belt Scale for High Flow Rate and Speed

The LBS belt scale is a versatile, continuous weighing solution ideally designed to fit a variety of conveyor types, including high-speed and high-flow models, frequently employed in mines and cement plants. This industrial dosing device offers real-time measurement of bulk material flow conveyed on a metal apron, suitable for demanding environments. It enables a dynamic tare function without needing to empty the upstream silo beforehand. This belt scale automatically detects belt rotation, improving dosing efficiency using its speed detection wheel. Furthermore, it ensures accurate totalisation of cumulative weight, enabling monitoring and accurate regulation of material flows.

Gran - Impact Flowmeter for Granular Material

Continuous weighing of small granular free flowing materials. Totally enclosed, rugged construction with pressure equilibration channel. Not sensitive to material build-up the pendular system only measures horizontal forces. Maintenance free, no moving parts. Easy installation into material handling circuits. Wear protected material guiding funnel and impact plate.

Hasler - Model CLM85 and CLM90 - Calibration Chains

Calibration chains (CLM85 and CLM90) are essential accessories to any user of conveyor belt scales or weighbeltfeeders. It’s often very difficult to check the dynamic accuracy of a beltscale or a weighbeltfeeder installed in a continuous production line if there is no material deviation possibility for a drop test. Each CLM calibration chain consists of 1 hanging shaft with hook and several roller segments. The segment pitch is selected according to the weighbridge length.