Innovative Recycling Solutions, LLC products

Plastics

Water Ring Pelletizer

Pelletizing completes the recycling process. The pelletizing system (or die face cutters) is located at the very end of the line. The recycled material comes out of the die plate in form of `spaghetti` and it is `cut` by a series of rotating blades into small cylinders which are cooled with water and then dried in a centrifuge. During this stage, the material takes on the form of a granule (or pellet). The TDA water ring pelletizer features an innovative design concept which allows smoother and faster production starts and changeovers compared to former models. It can be installed on lines for average to large production capacities, suited to recycling most plastics (PE, PP, PS, ABS, MASTER, COMPOUNDING and others).

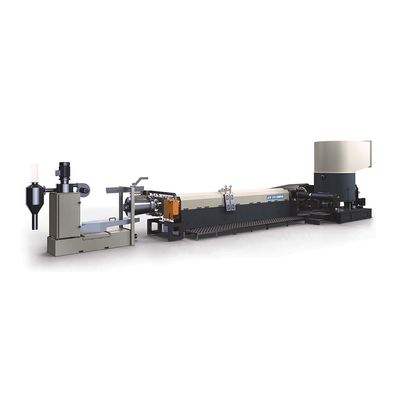

Compac System

The COMPAC system is designed to deal with special materials such as film, fibers, fabrics and yarns and consists of a feeder equipped with a cutter-compactor, extruder, screen changer and a pelletizer. This type of line is available in several models depending on the required output. GM65 - GM90 - GM105 - GM125 - GM160 - GM180.

Ecotronic - Cutter Compactor

The NEW patent pending ECOTRONIC, a drive system to control the Compac AFT Cutter-Compactor, was first developed for PET solutions. Together with our screw profile and degassing system the ECOTRONIC control has achieved impressive results.

Gamma Meccanica - Cutter Compactor

The Trim-Co is the smallest line made by Gamma Meccanica. As all the lines belonging to the COMPAC range, Trim-Co consists of a cutter-compactor, extruder and a pelletizer. The Trim-Co is designed to regenerate materials such as film, fibers, fabrics and yarns. The line is particularly suitable for regenerating HDPE, LDPE, PE and PP in the shape of film, shopping bags, small cut reels and production waste.

Underwater Pelletizer

The TI underwater pelletizer is indicated for the granulation of all plastic materials with high fluidity. The die is completely immersed in the cooling water, creating a layer of film around the granules as soon as they come out of the die.

Screen Changers

The screen changer is a fundamental device because it filters the material coming out of the extruder before the granulation stage and guarantees the total purity and quality of the end product.

AFT Cutter Compacter

The capacity can vary according to the type and the characteristics of the material which is to be processed: percentage of contamination, bulk density, moisture, viscosity, etc.

Forced Feeders - Silos

Variations available depending on the material, size of the extruder, plant specifications and storage requirements.

Tandem Solution

Tandem is an exciting technology that we are developing to work in congress with either one of our superior feeding technologies, i.e. FORCE FEED and COMPAC . This technology works with two extruders in “tandem” to one another.

PET/PA Line Recycling Lines

Recycling lines for PET and PA film, fibers and sheet now have a system solution that yields better results than that of our competitors with our new ECOTRONIC control solution. The PET/PA line consists of: dehumidifier, extruder, filter, pelletizer.