J. Huesa Water Technology products

J. Huesa - Filtration System

Physical operation involving the passing of water through a filtering medium with the goal of separating out the fluid from the material that is carried along with it. The filter medium is always either a support or a bed, called support filtration or bed filtration, respectively.

J. Huesa - Electrodeionization (EDI) System

Refining technique that achieves ultrapure water by combining ion exchange with electrodialysis. With EDI, an exchange resin is introduced into the compartments between the membranes of the electrodialysis cells. The ion exchange resin minimizes ion leakage typical of ion exchange, eliminating the requirement of regenerants, with a consequent reduction in the use of chemicals.

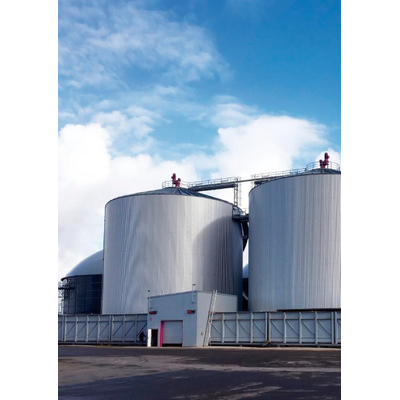

J. Huesa - Anaerobic Biological Treatment Plant

Wastewater contains high levels of organic material, nutrients (mainly nitrogen and phosphorus), bacteria, and pathogens. The objective of biological treatment is to remove these, which can be achieved through the metabolic action of different strains of microorganisms.

J. Huesa - Microfiltration System

Filtration within a porosity zone between 0.1 µm – 10 µm, which allows the removal of suspended solids, fine particles, colloids, algae, and microorganisms, among other elements. The force that facilitates the passage of substances through the membrane comes from a pressure gradient.

J. Huesa - Reversible Electrodialysis (EDR) Plant

Electrodialysis is a process of electrochemical separation in which ions are transferred through ion exchange membranes by means of a continuous current. In this case, the membranes have ionic groups attached to them in such a way that allows the passage of ions of the opposite charge to their own, and always from the less concentrated solution to the more concentrated one, which can cause significant salt concentrations to form around the membranes, resulting in precipitations and even scaling. To avoid these problems, reversible electrodialysis(EDR) was developed, which involves periodically changing the polarity of the electrodes (three or four times every hour). This reversion functions as a self-cleaning system for the membranes. Depending on the type and configuration of the membranes, different water treatment results are achieved.

J. Huesa - Sludge Treatmen Plant

Different water treatments produce a series of wastes that can be solid (which are incinerated or brought to landfills) or sludge, which can have a liquid or semi-solid consistency. The composition of the sludge depends on the nature of the initial water contamination, the treatment to which the water has been subjected, and its hydrophilic colloidal matter content. Sludge management aims to reduce sludge volume in order to minimize operating costs.

J. Huesa - Ultrafiltration (UF) System

Ultrafiltration is a membrane technology that takes place within a membrane porosity range between 0.001 and 0.1 µm. This process is used for the selective removal of suspended matter, particles, large macromolecules, colloidal matter, or microorganisms, but does not remove ions or dissolved matter as reverse osmosis does.

J. Huesa - Disinfection Systems

Technology that aims for the destruction or inactivation of pathogenic organisms present in water. Most of these pathogens are destroyed and/or eliminated during physical-chemical water treatment operations such as filtration. However, sometimes a specific disinfection treatment is necessary to ensure proper sanitary protection.

J. Huesa - Deodorization System

The emission of foul industrial odors is often linked to production processes, for example in the paper industry, and oil and gas production, but it can also be due to wastewater treatment (due to the reactions that take place in the different types of treatments used).

J. Huesa - Nanofiltration System

Nanofiltration is a membrane filtration process that takes place in a porosity range between 150-500 Dalton, depending on the molecular structure (pore size around 1 nm), which achieves, among other things, the separation of polyvalent ions with an effectiveness of more than 95 %, as well as organic matter of low molecular weight (sugar, proteins, etc.).