Mannesmann Line Pipe GmbH services

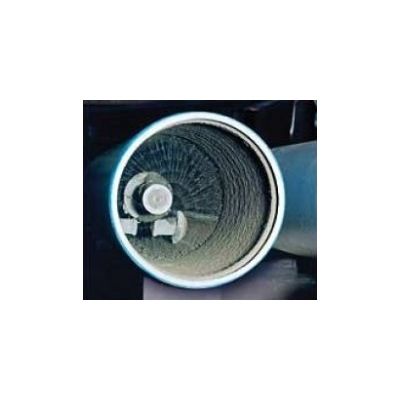

Steel Pipe Production with HFI Welding

Longitudinal welding at SALZGITTER MANNESMANN LINE PIPE is done using the High -Frequency Induction (HFI) process, an electric resistance welding (ERW) technique. In this process, the strip edges are heated to welding temperature and pressed together by rollers without any filler metals to give a homogeneous longitudinal weld.

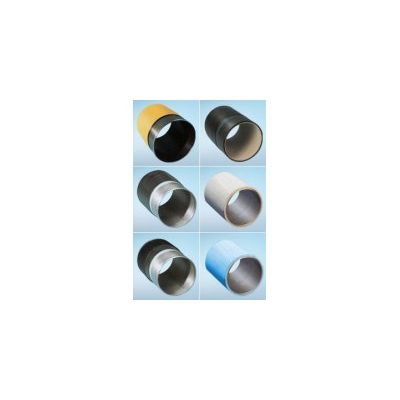

Plastic Coating

We offer a full range of coatings and linings for all requirements in terms of soil conditions and media to be transported. TheMAPEC®plastic coating provides highly effective protection against corrosion and mechanical damage. Given the many fields of service for line pipe, corrosion protection needs to be both tough and reliable. SALZGITTER MANNESMANN LINE PIPE has been involved in the development and application of active and passive pipe protection systems for decades.MAPEC®is the registered trade mark for a three-layer plastic coating. It`s a coating that offers the ultimate in reliability. AndMAPEC®has variants for even the most difficult terrain as well as operating temperatures right up to 100°C.

Fiber Cement Mortar Coating

Pipes with MAPEC coatings can be additionally protected with different fibrous cement mortar (FCM) coatings in accordance with DVGW Worksheet GW 340. Originally developed for protection against mechanical damage, FCM coating is now available in diverse variants for trenchless pipe laying or as ballast coating with an extra thick coating layer.

Cement Mortar Lining

The main purpose of linings for pipe conveying aqueous media is to provide safe, reliable and lasting corrosion protection. Cement mortar lining fulfils this purpose in two ways. First, it is an effective barrier between the pipe and the medium. At the same time, however, the high alkalinity of mortar actively inhibits corrosion. A further decisive advantage is mortar`s self-healing property, i.e. cracks in the lining close spontaneously in non-aggressive waters.

Research & Development

We maintain close contact with national and international institutes, notably theSalzgitter Mannesmann Research Institute, because we aim not only to continuously improve the HFI welding process but also to promote and support new product developments for the benefit of our customers.

Logistics Services

As a competent logistics partner, Salzgitter Mannesmann Line Pipe is committed not only to the appropriate and safe transport of its products. It also attaches great importance to a sound and efficient logistics chain – from the plant to the agreed destination.