- Home

- Companies

- NPO Dekanter, LLC

- Products

NPO Dekanter, LLC products

NPO Dekanter - Model STP-15 - Soil Treatment Plant

Soil Treatment Plants STP-15 series are being produced since 2009. They can process oil sludge and oil contaminated soils regardless of the percentage content of water, hydrocarbons and mechanical impurities. Our company manufactures, assembling and shipping the Soil Treatment Plant STP-15. If necessary, STP-15 units can be completed with additional centrifugation modules (CM) according to the needs of customers on the basis of centrifuges and decanters manufactured in Europe. STP-15 units have all necessary permits, including a positive conclusion of the State Ecological Expertise of Russian Federation.

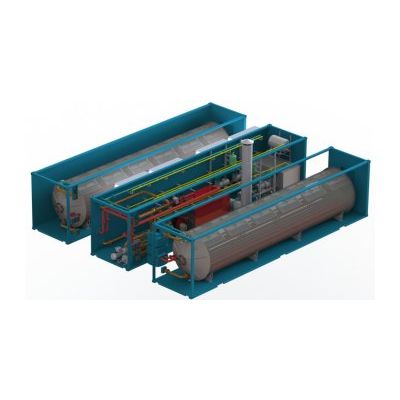

NPO Dekanter - Model TDP Factor-500 - Thermal Destruction Plant

Mobile Thermal Destruction plants Factor-500 (also called as TDP-500) are intended for thermal utilization of oil slimes with extremely high content of mechanical impurity, oil-contaminated soil, drill sludge, oily wastes formed at emergency leaks of oil and oil products, and other loose and pastelike wastes. These plants have no analogs in the market — they completely fit into the standard sea container 40ft and can be transported from one working platform to another with the subsequent start within a day. Scopes: oil processing and oil-extracting branches, landfields of dangerous wastes, industrial enterprises, enterprises of an oil and gas complex, sea and river ports. The units are recommended to be applied when all other methods are no longer efficient, for instance, in the regions where bioremediation is not carried out or sludge cannot be decontaminated in any other way.

Dekanters and Separators

Model MC Series - Modules Centrifugal Separation and Purification of Drilling and Oil Sludge

The units of the MC are modular systems that are mounted on an open frame or standard shipping containers that allow for working offline and having the opportunity of mobile transport to the venue of the required range of works. Depending on the configuration, they can perform the following types of separation: separation of solids from liquids (sludge thickening), a rough separation of liquids with solids separation, fine separation for the final purification of the release of water, hydrocarbons and other liquids.

Oil Sludge Utilization

Model Factor-2M - Small Units for Burning of Slop-Oil

Factor – 2M unit is designated for thermal utilization (burning) of oil wastes.

Model Factor-1M - Waste Oil Burning Compact Units

Factor-1M unit is used for thermal utilization of oil sludges of small volumes, oily soils, exhausted combustible adsorbents, oil-polluted grass and straw, wood stained with hydrocarbons and other similar combustible wastes.

Model BRNSH-10 - Separation Block for Oil Sludges and Mazut Made on the Basis of Vacuum

BRNSH-10 allows removing water from some liquid oil products, including waterlogged oil fuel and oil sludge. Evaporating is done under vacuum, which allows reaching high efficiency with low costs. Average prime cost of drying 1 ton of oil fuel of M-100 type from 25% to 0.5% of humidity is equal to about 550 roubles.

Scrubber Liquid Purification Units

Scrubber liquid purification for further purification of exhaust flue gases formed in the incineration of sludge in installations Factor series.

Reservoir Cleaning

KERBER - Mobile Complex of Tank Cleaning Systems

Light and heavy oil and reservoir cleaning and washing systems Kerber. The mobile system Kerber is designed for cleaning and washing from oil sludge and other sediments tanks used for storing heavy and light oil and petroleum products. Kerber was designed based on UOG-15 series oil sludge treatment complexes. Our company produces a line of these systems for different capacity and designs of the oil storage facilities. This unit could be used for tanks with the capacity upto 100,000 m³.

Oil Regeneration

Model Melioform-OMM - Mineral Oils Purification and Clarification Unit

Melioform-OMM is the equipment unit designated to recover commercial properties of the product after transportation and storage by means of removing mechanical admixtures and water with clarification by means of neutralization of products of ageing and others in small dispersed state; cleansing turbine, transformer, industrial, motor and other types of oils with increased content of pollution and water and their clarification.

Model MFZS Series - Oil Filtration and Pouring Stations

The units of MFZS series are produced for pumping over and filtering of oil from mechanical admixtures with fracture dimensions not more than 70 micron. As a rule, such filtering is implemented before burning of oil in special air heating equipment. It allows to avoid blinding of burner nozzles and more ecological emission.