OR-TEC, Incorporated products

Sludge Dewatering

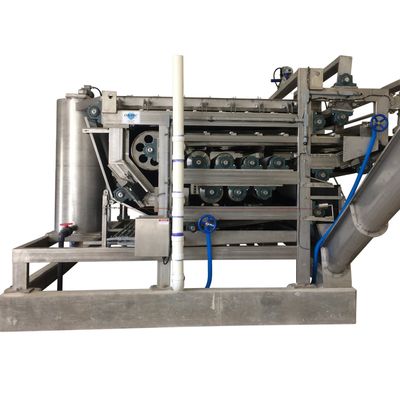

OR-TEC Gemini - Full Sized Belt Press

A full sized double belt system ideal for the medium to large size WWTP. The OR-TEC Gemini Belt Press is a double belt system ideal for the medium to large size WWTP. The unit has a large flocculation tank with a variable speed mixer which allows the sludge and polymer solution to be thoroughly mixed. The variable speed mixer allows operators to easily change the mixing energy which helps ensure the best possible flocculation.

OR-TEC Mark - Model II - Belt Press

An affordable single belt press system for the small to medium WWTP. If you`re looking for an economical and simple solution to your dewatering concerns, you`ll find an answer in the OR-TEC MARK II Belt Press System. Designed with ease of operation, low maintenance, cost effectiveness and dewatering efficiency in mind, the MARK II is a proven leader in the municipal, industrial and agricultural realms. It is constructed entirely of stainless steel and can be trailer mounted for multiple site operation. It is an excellent solution for small to medium size plants where babysitting equipment is not an option and reliable, high quality equipment is a must.

OR-TEC Xpress - Model 2 and 3 - Belt Press

A Double or Triple Belt Press for municipal and industrial wastewater plants. The OR-TEC xpress Belt Press System is the perfect double or triple belt press for the municipal and industrial wastewater treatment plants. It is designed to be easy to install, operate and maintain.

OR-TEC - Belt Thickener

This rugged and easily operated system can be set-up for thickening or dewatering. If you`re looking for an economical and simple solution to your thickening concerns, you`ll find an answer in the OR-TEC Thickener System. Designed with ease of operation, low maintenance, cost effectiveness and efficiency in mind, the OR-TEC Thickener is a proven leader in the municipal, industrial and agricultural realms. It is constructed entirely of stainless steel and can be trailer mounted for multiple site operation. It is an excellent solution for small to medium size plants where babysitting equipment is not an option and reliable, high quality equipment is a must.

OR-TEC - Rocker Screw Press

An enclosed, high performance sludge dewatering system. The OR-TEC Rocker Screw Press utilizes a central screw, a rocking multi-disc filter and variable back pressure plate to increase pressure on flocculated sludge and produce an exceptionally dry cake. There is no physical contact between the screw and the multi-disc filter or between each disc in the filter which prevents unnecessary wear and tear. With low electrical, water and polymer usage, and high solids cake and capture rates the system is very cost effective, easy to install, operate and maintain. An excellent solution for small to medium size plants where babysitting equipment is not an option and reliable, high quality equipment is a must.

Screens & Grit

Or-Tec Blue Whale - Micro Bar Screen

The world`s only super fine mechanical bar screen with openings down to 1mm. The Micro Bar Screen is a superfine mechanical bar screen with openings as small as 1mm (0.03"). The Micro Bar Screen removes the vast majority of hairs, rags and stringy material which pass through screens with larger openings. These smaller openings help to prevent matting or ragging forming on items such as pumps, mechanical seals, diffusers and rotating equipment. Maintenance on these items is reduced to practically zero as ragging and matting no longer builds up.

OR-TEC - Constant Current Screen and Grit System

A grit removal system which automatically adjusts based on flow. The OR-TEC Blue Micro Bar Current Grit System completely replaces a traditional headworks of a wastewater treatment plant and provides an easy to install, flange in/flange screening and grit system. Gone is the need for concrete channels for screens, concrete settling or vortex grit chambers. All that is needed to install the OR-TEC CGS is a level concrete pad and access to power and washwater. The OR-TEC CGTS Headworks is manufactured from stainless and has two distinct sections.

OR-TEC - Septage Receiver

Quick disconnect hook up, multiple washdown points, blockage free operation. The OR-TEC Septage Receiver screens, compacts and washes screenings directly from the septage hauling vehicle. The unit is simple to install and it ensures that the septage entering the plant has been thoroughly screened. Screenings are washed, compacted and elevated to a convenient height for disposal. The Septage Receiver body is constructed of stainless steel. The screw can be constructed of stainless steel or epoxy coated hardened steel.

OR-TEC - Screw Screen Compactor

An efficient and affordable wastewater screen. An efficient and affordable wastewater screen. The OR-TEC Screw Screen Compactor screens, compacts, washes and lifts screenings to a convenient height for ease of disposal. The unit is provided with perforation sizes ranging from 2mm to 6 mm for municipal wastewater and 0.25mm to 2mm wedgewire for industrial applications. The unit can be mounted at an angle in a channel, in a tank or supplied for vertical installation. The shaftless design of the screw auger prevents rags or stringy material from becoming wrapped around the screw. Units are available without compactor where screening only is required. The Screw Screen Compactor body is constructed of stainless steel. The screw can also be constructed of stainless steel or epoxy coated hardened carbon steel

OR-TEC - Rotary Brush Screen

Perfect for Membrane Bioreactors (MBR) and the headworks of WWTP. The OR-TEC Rotary Brush screen is manufactured from stainless steel and is designed to remove fibers, hair and other foreign objects from a waste stream. It uses a static stainless steel perforated semi cylindrical screen bed for this purpose. This bed is continually cleaned by a stainless steel armature with brushes. The brushes are selected based on the particular waste and gently sweep the screen bed. This action cleans the screen bed but puts no pressure on the screen bed. This prevents the distortion and wear that can occur on other types of perforated fine screens. The brushes are cleaned by a stainless steel scraper blade and discharged outside of the machine. OR-TEC Rotary Screen brushes have approximately 1 inch of adjustment so even in situations with aggressive or abrasive wastes the brushes last many years.