- Home

- Companies

- OR-TEC, Incorporated

- Products

- OR-TEC Gemini - Full Sized Belt Press

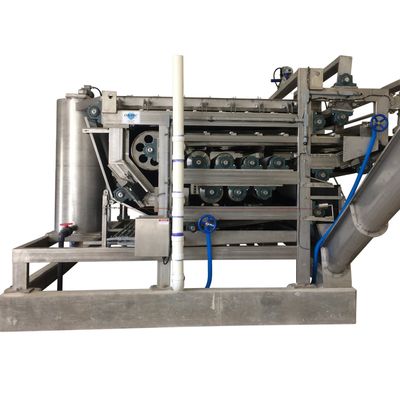

OR-TEC Gemini - Full Sized Belt Press

A full sized double belt system ideal for the medium to large size WWTP. The OR-TEC Gemini Belt Press is a double belt system ideal for the medium to large size WWTP. The unit has a large flocculation tank with a variable speed mixer which allows the sludge and polymer solution to be thoroughly mixed. The variable speed mixer allows operators to easily change the mixing energy which helps ensure the best possible flocculation.

Following the flocculation tank the sludge enters a large gravity zone where plows and dewatering rollers begins the process of thickening the sludge. From here the thickened sludge enters a low pressure zone which features a large perforated stainless steel roller followed by an increasing pressure wedge zone. The final dewatering zone is a high pressure area where multiple rollers of decreasing diameter continue to squeeze and dewater the sludge.

The OR-TEC Gemini Belt Press provides a large dry solids throughput combined with an excellent final cake, low polymer usage and a high solids capture rate.

- Large gravity zone with plows and dewatering rollers

- Perforated roller and wedge low pressure zone

- High Pressure 8 or more roller squeezing zone

- Auto start-up, run and shutdown

- Automatic Belt Tracking

- Sludge Cake Monitoring System

- Electric actuation (no hydraulics or pneumatics needed)

- Fully automated easy to use Touchscreen Controls

- Skid mounted, turnkey, factory tested complete system

- Stainless steel frame, flocculation tank, mixers, rollers, pans, trays and fasteners

- Highest quality pumps, motors and geardrives

- OR-TEC designed and manufactured Polymer Dosing System and Screw Auger ensures 100% equipment compatibility

- Onboard flow meters

- Available with SCADA ready controls

- Many other features and configurations available

All OR-TEC Belt Press Systems are designed, engineered, manufactured and assembled in the USA

Chemical Dosing

An OR-TEC Blend emulsion polymer feed system automatically makes up and delivers the polymer and water solution to the injection site. As an alternate, a solution of suitable polymer is made up in a stainless steel chemical mixing / storage tank. The tank is usually designed with a capacity for one day operation of the system.

Sludge is pumped to a stainless steel flocculation tank by a variable capacity pump. Prepared polymer is simultaneously injected to the inlet of the flocculation tank by a variable speed chemical dosing pump. Here thorough mixing occurs aided by a variable speed flocculator fitted in the tank. Speed adjustments are manual.

Flocculated sludge flows from the flocculator down a sludge feed chute. This chute provides gentle, even distribution of the sludge over the gravity drainage section and a uniform thickness on the dewatering belt. The drainage area allows for the separation of the free water contained within the sludge and its consequent discharge into the drainage tray. A series of adjustable dewatering plows also aid the dewatering process. The drainage area is sealed by polypropylene skirting that is bolted to the top trays and rests on the filter cloth.

From the gravity zone the sludge travels to the squeezing zone. Here further liquid removal is achieved as the two dewatering belts are gradually brought together and the sludge is pressed between them.

The high pressure dewatering zone consists of a series of rubber covered rollers. The sludge is pressed between the two belts as it travels through this zone. The gradual decrease in the diameter of these squeezing rollers ensures good dewatering and high final cake solids.

Dewatered sludge is continuously removed by fixed scraper blades acting against the final rollers and allowed to fall into a horizontal stainless steel conveyor. The conveyor can transport the sludge cake to the outside of the building. Sludge cake can also be elevated with a stainless steel inclined screw auger for discharge to a waste hauling vehicle for off-site removal. A dry cake pump can be used as an alternative to the conveyor or auger.

The filter belts are continually washed by pump generated high pressure water sprayed through fine nozzles. Belt wash water and filtrate are collected in a stainless steel drainage tray. In most cases, the filtrate is acceptable as reuse for wash water, as is the final effluent of the W.W.T.P.

The system can be automatically controlled. Start-up is simple and requires a minimum of time. The unit`s design, incorporating variations in both speed of the main elements and in roller pressure, offers a high degree of flexibility to the user.