- Home

- Companies

- Quest-Tec Solutions

- Products

Quest-Tec Solutions products

Level-Trac Water Level Indicators

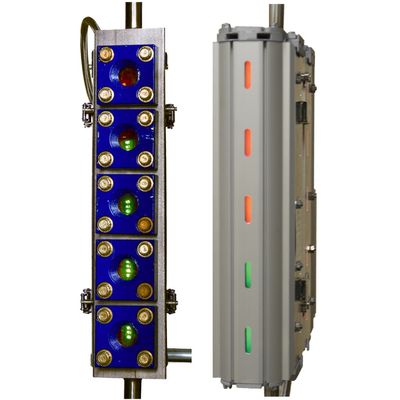

Level-Trac - Low Pressure Probe Manifold

The Level-Trac Model 500 probe manifold features sturdy construction in full compliance with ASME Section 1 requirements. Each column is custom built to the customer’s individual specifications. The chamber is a custom extrusion designed to provide full probe thread engagement. The Model 500 probe column may be used as an independent remote level indicator per ASME PG-60 Section 1, or as a traditional water column for the mounting of direct reading sight glasses. All piping connections are to user specifications.

Level-Trac - Medium Pressure Probe Manifold

The Level-Trac Model 501 probe column features sturdy construction in full compliance with ASME requirements. Each column is custom built to the customer’s individual specifications. The Model 501 Water Column may be used as an independent remote level indicator per ASME PG-60, or as a traditional water column for the mounting of direct reading sight glasses. All piping connections are to user specifications.

Level-Trac - Electronic Control Unit

The Level-Trac Model LT-210 Electronic Control Unit is a component of a remote level indication system, as described in ASME Section I, PG-60. The control unit may also be used as an alarm or trip device. Discrimination between water and steam is based on the significant difference in resistivity between the two states over the saturation range. The control unit interprets and displays the signal from up to 12 probes mounted in a probe manifold. Via voltage applied to the probe tip, conduction in the presence of water will occur between the tip and the inside wall of the column.

Magne-Trac Liquid Level Indicators

Magne-Trac - Magnetic Level Indicator

The Magne-Trac product line provides one of the safest and most economical ways to meet your level measurement requirements. In applications for extreme pressure, temperature, vibration, and highly corrosive or hazardous material, Magne-Trac gauge will perform where other fail. Features include lower installation costs, easy to read liquid level indication, and low maintenance. Constructed of non-magnetic materials including standard 316 SST. Exotic materials such as Alloy. 20 & Hastelloy C are available. Traditional inlet & outlet mounted design displaying liquid level to match the vessel level. Complete with flange end closure for accessibility to float. Magne-Trac chambers are available to ASME 31.1 and 31.3.

Magne-Trac - Magnetic Level Indicator + Bridle Chamber

The Magne-Trac Plus combines a Magne-Trac magnetic level indicator with a Bridle-Trac bypass chamber, in which a customer specified guided wave or non-contact radar may be installed. Although either instrument may be connected to the vessel, Questtec recommends that the bridle functions as the primary chamber. By using the magnetic gauge as the secondary chamber, the customer will have the option to rotate the indicator up to 180 degrees easily in the field. The two chambers may welded or flanged together; QTS recommends installing valves in between the magnetic gauge and bridle chamber so one may be isolated if necessary.

Magne-Trac - Magnetostrictive Level Transmitter

The MTLT-5000 is based upon the magnetostrictive principle. The sensing tube contains a wire which is pulsed at fixed time intervals. The interaction of the current pulse with the magnetic field created by the magnetic float causes a torsion stress wave to be induced in the wire. This torsion propagates along the wire at a known velocity, from the position of the magnetic float and toward both ends of the wire. A patented piezo-magnetic sensing element placed in the transmitter assembly converts the received mechanical torsion into an electrical return pulse. The microprocessor-based electronics measures the elapsed time between the start and return pulses and converts it into a 4-20 mA DC output which is proportional to the level being measured.

Bridle-Trac

Bridle-Trac - Bridle Chamber

The Questtec Solutions Bridle-Trac utilizes a pipe chamber mounted directly to a vessel with two or more process connections. These connections act as an inlet and outlet that allow the liquid level in the pipe chamber to match the level in the process vessel. A bridle-trac may be referred to in the industry as a bridle chamber, a stilling well, a bypass chamber, a cage or a standpipe. It may be used with a customer specified radar for level measurement.

Steam-Trac

Steam-Trac - Direct Reading Bi-Color Ported Steam / Water Gauges

The Steam-Trac STB-3000 Bi-Color Ported Gauge must be used with a red/green filter illuminator. The gauge chamber is constructed with opposing ports at an angle so that red light will pass unimpeded through the gauge in the steam phase. When water is present, refraction will allow green light, only, to pass through. The result is a clear visual indication of water level. All connections and materials fully comply with ASME requirements, and the gauge may be used as a Direct Reading Sight Glass for compliance to ASME PG-60. Since water appears completely different than steam, it is not necessary to have overlapping sections. Multiple section gauges will have a continuous chamber constructed of a single piece of bar. An Illuminator is required for this gauge to work properly.

Glass-Trac - Automated Slide Ruler

Glass-Trac Reflex - Liquid Level Gauges and Valves

Glass-Trac Reflex Gauges use prism glass to provide an excellent indication of the liquid level. All liquids appear black in high contrast to the mirror-like surface above. This clean line of separation can be sighted from many yards away. Reflex Gauges are made in three pressures series (maximum 4000 psig @ 100ºF) and are tapped for ½” or ¾” NPT connections. The standard Glass-Trac level gauges are designed for minimum -20ºF service. On Glass-Trac Reflex Close Hook-up Gauges with ½” NPT connections, the center-to-center dimensions is the same as the overall length on standard gauges. On Close Hook-up Gauges with ¾” NPT connections, the center-to-center dimensions is the same as the overall length on standard gauges plus ?”.

Armor-Trac

Armor-Trac - Sight Flow Indicator

Questtec Solution’s Sight Flow Indicator is straightforward and dependable way to determine the flow of liquid in a process line for low pressure industrial, sterile, and hygienic applications. Horizontal installation provides direct views through a transparent sight tube for clear visibility. Minimal wetted parts and construction elements make the Questtec Sight Flow Indicator maintenance-free. Containing only an armored shield, sight tube, self-sealing Teflon® Max-Seal inserts, and Borosilicate sight tubing. Removal or disassembly of the Sight Flow is not required once installed, even for routine cleanings and inspections. Questtec Solution’s Sight Flow Indicators are 100% welded to secure bolting and solidify seals in cases of heavy vibration to prevent leaks.