Schroeder Valves GmbH & Co. KG products

Schroeder - Automatic Recirculation Valve

SHP series automatic recirculation valve for high pressure applications, low-wear operation and high load fluctuations . The SHP series automatic recirculation valve protects pumps and equipment from damage that can occur due to the flow rate falling below the permissible minimum. The innovative design ensures that pumps and equipment are reliably protected, even in situations involving highly fluctuating pump loads and long periods of operation under extreme partial load conditions.

Schroeder - Minimum Flow Valves

The minimum flow valves from our SIP series is the ideal valve for applications with pressures between 140 and 250 bar in systems with continuous operation, even at load points below the pump minimum quantity. The SIP controls the bypass by means of a multi-stage piston, which enables a defined multi-stage pressure reduction for all flow rates and also guarantees cavitation-free operation at all times. The piston of the SIP is actuated directly by the plug via a lever; the pressure is balanced to reduce the actuating forces. By means of pressure compensation, the actuating forces are reduced to such an extent that a pilot system (as with the SMA /SHP high-pressure series) is not required. With its properties, the SIP is particularly suitable for the protection of boiler feed pumps in combined cycle power plants (CCPP).

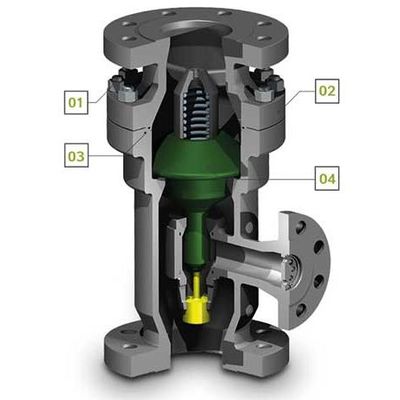

Schroeder - Automatic Recirculation Control (AR) Valves

The automatic recirculation control (AR) valves from our SSV series automatically protect centrifugal pumps against wear, total loss and damage, which can occur due to dry running or during low-load operation. Our recirculation valves have historically proven exceptional reliability and low pressure loss over time. They are not susceptible to interference and are very low maintenance. In addition, they require no additional power supply or any kind of control unit, thus ensuring low operating costs.

Schroeder - Multi-Functional Valve

The Schroeder SMV series multi-functional valve is an automatic recirculation valve that is equipped with an automatic venting nozzle in addition to the minimum flow control and non-return device in the main feed. It permanently ensures that the stationary pump and standby pump are automatically vented and thus remain filled with liquid at all times.

Schroeder - Automatic Minimum Flow System

The SMA 63/64 automatic minimum flow system is a protective pump fitting. It automatically protects centrifugal pumps against damage that may occur as a result of the partial evaporation of the pump content when the pumps are operated under low load. As soon as the main pump flow falls below a predetermined value, the valve opens the bypass and safely drains the minimum volume, even if the pumping volume in the main flow direction drops to zero.

Schroeder - High Pressure Control Valves

The SR/SA valve type has been designed to control liquid media at high and very high pressures. The control valve is able to safely withstand pressures up to 600 bar and media temperatures of up to 400 °C. It is suitable for use both as a stand-alone shut-off valve (type SA) as well as for flow-control (type SR). When used for pump protection, SR/SA valves are mainly used in modern process control and monitoring systems. They make it possible to accurately adjust the minimum volume regulation to our customers` system requirements. The use of actuators and sensors allows the valve to be fully integrated in modern process technology. SR/SA valves therefore extend Schroeder`s product range to include control valves. They make a valuable contribution to low-energy, low-wearing pump operation.

Schroeder - Multiport Throttles Valves

Multiport throttles are used to reduce the pressure and flow volume of liquid media. The multiport throttles are used in nominal widths ranging from DN20 to DN500, in pressure steps up to PN640 and up to a permissible media temperature of 400°C. The throttle housings are normally made of 1.0460 (C22.8) steel suitable for pressurized vessels, but can also be made of various types of stainless steel, depending on the medium.

Schroeder - Back Pressure Device

Our back pressure device does not allow the static pressure in the upstream pipe to fall below a defined minimum value. It does this independently of the flow volume. This means that the specified minimum pressure is maintained, from the nominal flow rate to the smallest volume. Normally back pressure devices are used to avoid cavitation and partial evaporation in the pumping medium. By increasing the pressure level in the system component to be protected, they stop local steam pressure from falling below requirements. The SDV has an integrated return function, i.e. the system is also protected against reverse flow if needed.

Schroeder - Automatic Recirculation Smartline Valve

Our product range, smartline, is an automatic recirculation valve for the protection of standard centrifugal pumps. The valves of the smartline range automatically protect the pumps against wear, total failure and damage caused by dry running or during low-load operation. The smartline valves are available in various sizes, all of which are located in the low-pressure range. They are suitable for various media and for admissible average medium temperatures between -50°C and 200°C.