- Home

- Companies

- Source Technology

- Products

Source Technology products

Powerheater - Processing Equipment

Model 100 - PowerHeater

The PowerHeater technology is based on the principles of extrusion technology. The PowerHeater process is based on transferring mechanical and thermal energy into a meat emulsion in order to coagulate the protein and any potential sources of carbohydrate. The technology makes it possible to transform simple, meat-based formulas into a very textured meat-alike product. Capacity of 100-300 kg/hour.

Model 100-3 - PowerHeater

The PowerHeater technology is based on the principles of extrusion technology. The PowerHeater process is based on transferring mechanical and thermal energy into a meat emulsion in order to coagulate the protein and any potential sources of carbohydrate. The technology makes it possible to transform simple, meat-based formulas into a very textured meat-alike product. Capacity of 100-900 kg/hour.

Inline Analysis

Bulk Density System - BDS

The Bulk Density System provides frequent inline sampling and analysis of bulk density, moisture (option) as well as visual product inspection (option). A very high measuring accuracy for all type of pellets, which ensures superior control of essential processing equipment, e.g. extruders and dryers. Running frequent analyses of pellet quality helps minimize problems such as over or under-filled bags, mouth-feel, starch gelatinization, bacteria growth, as well as fat absorption.

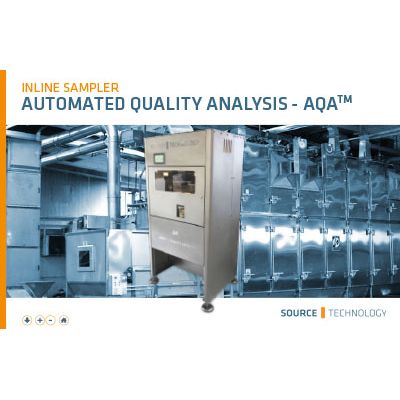

Automated Quality Analysis - AQA

The Automated Quality Analysis has an integrated grinder installed, which grinds the product prior to measuring. The AQA can be configured to measure numerous parameters such as bulk density, moisture, water activity, NIR, and product sizing.