Williams Patent Crusher & Pulverizer Co., Inc. products

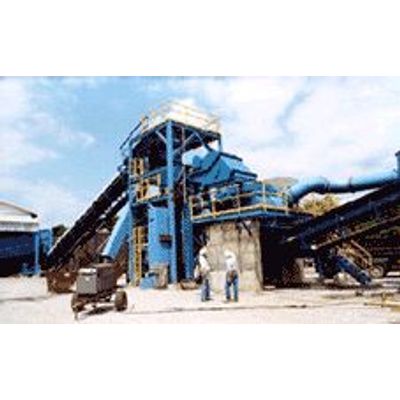

Impact Dryer Mills

Williams - Impact Dryer Mills

Proven technology integrated into a complete system that simultaneously grinds and dries, accurately classifies, and conveys materials in one continuous, automated operation. Some of the many applications for Williams Impact Dryer Mills include: drying & grinding by-product gypsum from power plant scrubbers for wall board manufacturers; drying & grinding filter cake (as well as other finely divided agglomerates) to a fine, dry powder; reduce clays and other minerals, such as pigments, to extreme fineness; grinding coal to proper fineness for burning in suspension or coal gasification.

Pulverizers

Williams - Roller Mills

Williams is the acknowledged leader in Fluid Bed Roller Mill Design.

Hammer Mills

Williams - High Tonnage Hammer Mills

Williams manufactures a variety of big Hammer Mills to handle almost any high tonnage, size reduction job including:

Rocket - Sawdust Hammer Mills

The Williams Rocket Mill is designed for the rapid reduction of large quantities of non-abrasive materials such as cereals, animal and fish byproducts, sawdust, expeller cake, rags, and wood pulp to fluff.

Meteor - Hammer Mills

The Williams Meteor Mill is characterized by high hammer-tip speed to permit a fine product or to obtain specific characteristics in the finished product. This mill is particularly well suited for producing high-quality fluff for the absorbent medium and non-woven fiber markets. Features include:

Slugger Crushers

Williams Slugger Crushers have large feed openings and massive construction for the big, continuous jobs, either in hourly output or reduction ratio. Specifically, they feature:

Hammer Mills

NF and GA mills are `overrunning` machines where the material is reduced on the breaker plates before being further reduced on the grates.

Hammer Mills

The Williams GP, or General Purpose Mill is a simple, rugged answer to many small and medium capacity grinding jobs. Features include:

Ring Crushers

Williams Ring Crushers are specially designed to reduce the size, and therefore the volume, of metal turnings, `bushelings`, or `clips` through efficient impact crushing. Where desired or appropriate, swing hammers can be substituted for the rings. Both types of crushers are built to produce their rated capacities, day after day, with minimum downtime.

Traveling Breaker Plates Mills

The Traveling Breaker Plate is designed to permit a Slugger Crusher to reduce muddy rock, clay, shale, or bauxite to 3/4` or smaller with no clogging. Among its features are: