- Home

- Companies

- ABB Measurement Products

- Products

- ABB - Model microFLO (μFLO) Series ...

ABB - Model microFLO (μFLO) Series -Basic Flow Computer

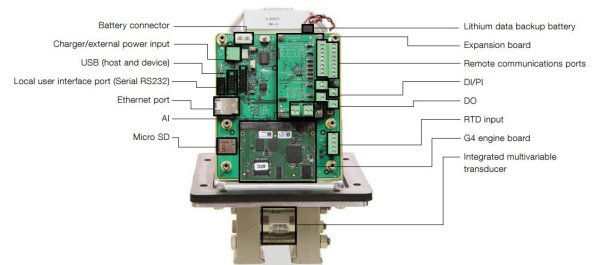

The microFLO (μFLO) series’ main board and Integrated Multivariable Transducer comprise a single unit. This “smaller” version with limited expansion capabilities is ideal for single-tube applications, but can accurately measure and monitor gas flow in compliance with AGA, API and ISO standards.

The μFLOG4 is an extremely accurate, reliable flow computer with the capability to measure and monitor gas flow in compliance with AGA, API and ISO standards. These units are also expandable to provide additional communications and IO options. Backward compatibility is always of concern and this unit provides that as well. The internal sensors and electronics are direct replacements for existing μFLOs. With low power, accuracy and system integrity built in, these devices are proven daily on thousands of sites. Totalflow products provide users the best opportunity for successful projects – site by site or system by system.

The μFLOG4 includes an Integrated high accuracy digital Muliti-Variable sensor (IMV) to measure both pressures and temperature. Two (2) versions of the sensor are available: one with differential pressure, static pressure and temperature for DP measurement applications, and one with static pressure and temperature for Linear measurement applications. The IMV is housed inside the flow computer enclosure and is characterized and calibrated at Totalflow’s factory. Multi-tube capability is available in each unit and is easily invoked with a few configuration changes and interface connection to external transducers, either digital or analog.

Hardware functionality of μFLOG4 devices can be extended by adding an optional expansion board.

Communications + IO expansion board includes:

- One (1) communications port. User selectable for RS232/RS422 or RS485

- One (1) DO

- One (1) DI/PI (supports up to 20 kHz)

- Two (2) Analog Inputs (4-20 mA or 1-5 Vdc)

The software design represents significant modularization through use of object oriented design principles. This allows a flexible and stable real time environment. Totalflow supplied objects (applications) can be enabled in our factory or by the user, one or more times on the same device. It is this framework that allows the support for multi-tube measurement.

Supported software applications continually grow. A sample of standard applications include:

- AGA3 orifice meter run

- ISO 5167 orifice meter run

- VCone meter run

- AGA7 meter run (rotary/turbine/ultrasonic)

- Coriolis Gas Application

- Liquid measurement (Linear) future

- Real-time data logger (trending)

- RAMS (alarming, exception reporting)

- Operators (simple custom math / logic)

- Selectable units (user selectable engineering units)

- Tank Level Application

- Therms master application

- Therms slave application

- NGC client

- XMV interface (for Multiple DP meter runs)

- Multiple protocols (Totalflow native low power, Modbus slave (binary/ASCII), Modbus master (binary/ASCII), Enron Modbus, LevelMaster, ABB 267CS/269CS XMV Multivariable)

- Low cost, high reliability design

- 203Mhz ARM920T 32 bit microprocessor

- Windows CE operating system (allows for a single software development environment for all G4 products)

- Integrated Ethernet 10Base-T port (full networking capabilities)

- USB host and USB device ports (ver 1.1): used for flashing new firmware and may be used as a fullspeed (12Mbs) local configuration and collection port

- µSD Card capability (future non-volatile memory expansion)

- Significant hardening against over-current / transients

- Positive Temperature Coefficient, resetting fuses and transient protection on

- VBatt and SWVBatt Outputs

- Digital Outputs

- Battery Charger Input

- Base IO on μFLOG4 main electronics board

- One (1) Digital Input (may be used as hi-speed PI input)

- One (1) Digital Output

- Battery Voltage

- Charger Voltage

- Low power design

- Aluminum powder coated enclosure (3R)

- Flexible accommodation of communications hardware

- Cost effective communications kits

- Stable time base (accurate integration)

- User selectable simple dual level security code data protection or enhanced user configurable Role Based Access Control (RBAC)

- Rechargeable, lead acid batteries with Solar, AC or DC charging options. Can also operate on 9 Vdc to 30 Vdc external power supply (without battery option only). User can enter date when batteries are installed and expected battery life. μFLOG4 will warn when expected life is reached. Can be used as an asset management tool. (Figure 2)

- Monitors user limits for detection, and reporting of abnormal conditions

- Defaults to 40 Days of hourly and 50 Days of daily data. User configurable.

- Defaults to 200 Events. User configurable.

- Complies with latest version of API 21.1 standard for custody measurement devices

- Flow and energy calculations per AGA3-85, AGA3-92, AGA-7, AGA-5, and ISO 5167

- Meets Flow Computer requirements as stated in AGA Report No. 9, ‘Measurement of Gas by Multi-pathUltrasonic Meters’

- Super compressibility calculations per NX-19, AGA8-92 Gross or Detail, ISO 12213

- Smart (temperature and pressure compensated) integral, factory calibrated, multivariable transducer (IMV)

- All calculations performed once per second

- Standard ‘High Speed Chart’ graphics for each run showing DP/Counts, Static Pressure, Temperature, and Flow rate.

- Frequency of sampled data is user configurable. Example chart in photo on page 5.

- Flow retention during user transducer calibration

- Selectable 3 or 5 point user calibration of Analog Inputs

- User definable DP no flow cut-off

- 100 ohm platinum RTD resistance curve fit with user programmable single point offset or 3/5 point user calibration for RTD input

- Hazardous Area Certification: CSA C/US; ATEX and IECEx

- Real time clock that continues running on lithium battery (maintains data backup)

- Advanced embedded data logger (Trending)

- Programmable alarm filtering

- Exception reporting capability

- Multiple protocol options including Totalflow packet protocol, various Modbus protocols and others

- User programmable Modbus register maps (both slave and master)

- User programmable math and logic sequences

- Multi-run measurement capability. One run measurement utilizing IMV, up to eight (8) additional runs per com port using MODBUS mult-variables.

- Sensor with housing and main electronics board are individually field replaceable. No longer necessary to replace the entire IMV in the event of a failure. All factory sensor calibration data is retained in a small electronics board that is part of the sensor and housing.