- Home

- Companies

- Technicon Acoustics, Inc

- Products

- Technicon-Acoustics - Acoustic ...

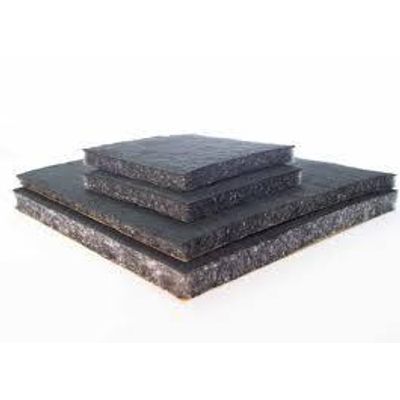

Technicon-Acoustics - Acoustic Absorbers

At Technicon Acoustics, we are the premier provider of acoustic and thermal solutions for North American original equipment manufacturers (OEMs). We specialize in the design, development, manufacture, and delivery of materials and products that absorb, block, and isolate sound and heat. One of our core product offerings is acoustic absorbers.

Acoustic absorbers are made from open-cell foam or porous fiber-based materials that prevent sound waves from reflecting off hard surfaces. They are used to line rigid surfaces—such as heavy equipment enclosures or operator cabs—to improve the acoustic conditions within the space rather than preventing noise from traveling into or out of it.

By integrating acoustic absorbers into their equipment, OEMs can significantly reduce the amount of reverberation experienced by end-users. As a result, operations are much quieter, and equipment operators are better protected against auditory injury.

For a more detailed explanation of sound absorption, check out our blog post, A Closer Look at Sound Damping vs. Absorption.

Sound waves are essentially vibrations. As the vibrations move through a solid, liquid, or gaseous medium, they cause the individual particles to vibrate. This motion passes from one particle to the next, allowing the sound wave to pass through the medium. When a sound wave reaches a sound-reflective surface, it bounces back into the space. As a result, the overall noise levels within the space increase as more and more sound waves are created and introduced.

As indicated above, acoustic absorbers prevent sound waves from reflecting off hard surfaces, which reduces the amount of airborne noise within a space. Their open-cell or porous structure allows them to take in and trap—rather than reflect—sound waves, converting the sound energy into thermal energy.

Acoustic absorbers are manufactured from foam or fiber, both of which offer the unique structure needed to dissipate sound waves. These materials come in several variations to suit different functional and aesthetic preferences.?At Technicon Acoustics, we offer the following types of acoustic absorbers:

- Foam-Based

- Fiber-Based

Our acoustic foams—also sometimes referred to as sound-absorbing or soundproof foams—are available in various thicknesses and facing options to allow customers to tailor their acoustic absorber solution to their exact needs. They come in two variations:

- POLYETHER FOAM. Polyether foam is made from open-cell polyurethane. In addition to its excellent sound absorption properties, it is lightweight, flexible, compressible, and thermally insulating.

- POLYESTER FOAM. Compared to polyether foam, polyester foam offers greater tensile strength.

OEMs apply acoustic absorbers within a wide range of equipment including engine enclosures, operator cabs, heavy equipment, medical devices, and more. By reducing operational noise levels, these materials enhance customer perception, improve operator alertness and awareness, and increase general productivity within the workplace.

Some examples of the equipment in which they are often used include:

The above list is not all-inclusive. Acoustic absorbers find application in many other pieces of industrial, commercial, and consumer equipment, including, but not limited to, compression housings, cowlings, and pumps.

Acoustic absorbers play a critical role in a variety of industrial, commercial, and consumer equipment—i.e., reducing the noise levels experienced in and around equipment. If you need acoustic absorbers for your equipment, turn to the experts at Technicon Acoustics.

At Technicon Acoustics, we offer foam- and fiber-based acoustic absorbers that can be customized to suit nearly any sound absorption application.