- Home

- Companies

- BoldEco Environment, Inc.

- Products

- VEnTO and Tsunami - Adaptive Fabric ...

VEnTO and Tsunami - Adaptive Fabric Filter Optimization Systems

VEnTO Benefits - Pulse Jet Baghouse: Fully-automated, adaptive controller Full-spectrum pressure cleaning (hi-med-low) Extends bag mfg guarantee by two additional years Reduces energy consumption Enhances capture of particulate and condensables Scroll down for more information on VEnTO.

- Decreases compartment cleaning and null times

- Extends bag life by reducing blinding

- Reduces particle bleed-through and pressure drop

- Increases baghouse capacity - saves energy

- Maintains filter cake bonds - reduces fine particulate

Scroll down for more information on Tsunami

To meet more aggressive particulate emissions standards, plant managers are increasingly retrofitting baghouses with membrane filtration elements. While the filtration capacity of these materials is far greater than with fabric bags, frequent replacement of advanced membrane bags make up the largest maintenance expense of a modern pulse-jet fabric filter. Conventional pulse controllers can further shorten the useful life of membrane bags by accelerating the rate of failure, causing exceedances of permissible dust emissions. To increase reliability and extend the useful life of high quality membrane filtration elements, BoldEco developed a smart baghouse controller which maximizes membrane bag integrity throughout its lifecycle. This patent pending device is the BoldEco VEnTO™ (Variable Energy - Timing Optimized) Smart Fabric Filter Controller.

In the basic mechanism for bag cleaning, a short pulse of compressed air just above the tubesheet generates a pressure shock-wave down the length of the bag which results in the removal of the outer dust layer on the filter media once the radial velocity imparted to the outer walls reaches the mechanical limits of the bag. Intuitively, this implies that the higher the impulse amplitude, the more thorough the cleaning of the bag, but this is not true in the case of membrane bags. Instead, over time, work-hardening of the membrane causes premature failure of the bag material.

During extensive testing in BoldEco’s European test facility, we measured the pressure inside both fabric and membrane bags at several locations and under varying conditions, using an oscilloscope connected to high velocity pressure transducers sewn directly onto the filter media. The results evidenced that the pressure level inside the bag directly correlates to the filter media radial acceleration, and therefore to media stress. In other words, minimizing the pressure required for a cleaning cycle maximizes bag life.

Key Pulse Cleaning Variables

Further analyses demonstrated that peak pressure inside the bag correlates to several critical filter media variables:

- length-to-diameter ratio

- pressure drop

- material permeability

- pulse valve size

- bags per pulse

- pulse air pressure

- blow pipe dimension

- venturi efficiency

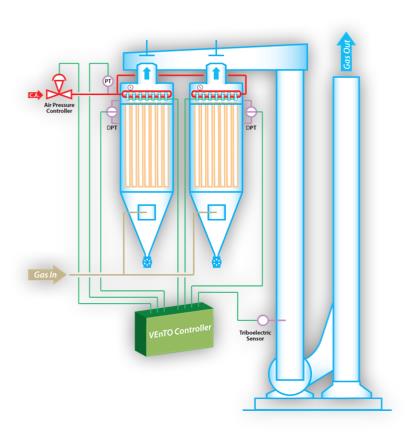

The BoldEco VEnTO™ control system comes complete with an electronic compressed air regulating system and dedicated differential pressure (DP) transmitters. VEnTO™ controls the DP by managing three key variables, namely compressed air pressure, solenoid excitation time and cleaning frequency. The system works completely in automatic mode, modifying the cleaning parameters in order to optimize the cleaning cycle relative to bag condition. Fundamentally, VEnTO™ accomplishes this by confining the pulse to either a high-pressure pulse with a short duration time or a low-pressure pulse with a long duration and all points between. As a result, the BoldEco VEnTo™ controller typically extends the expected membrane filtration lifetime in a conventional pulse jet fabric filter by an average of two years. VEnTO™ also provides the additional benefit of conserving energy by significantly reducing compressed air consumption.

PLC-Based Architecture

The VEnTO™ PLC-based architecture facilitates the use of configurable remote I/O drops, minimizing the cost of the retrofit and enabling integration with existing plant distributed controls.

Main Benefits of VEnTO

- Extends bag life- two year guarantee

- Reduces energy consumption

- Enhances capture of particulates and condensibles

Due to the unique experience of BoldEco Environment and with the implemenation of new technologies, such as the newly developed Vento Controller, CFD Technology and ePTFE membrane filter media, one can expect 5-6 years of bag life under normal use. With the installation of a Vento Controller BoldEco will DOUBLE a manufacturer`s warranty on bag life. Ask us for details.

Our technical department is specialized in the analysis, design and supply of custom engineered fabric filter retrofit technologies and in the supply, erection and commissioning of the new system, including performance guarantees.

Filter accessories can be selected for baghouses with various bag lengths, from 3 to 10 meters (10 to 33 feet).