- Home

- Companies

- AMETEK Process Instruments

- Products

- AMETEK PI - Model 920 - Hot/Wet Multi ...

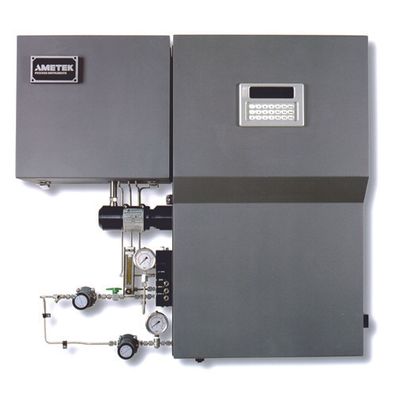

AMETEK PI - Model 920 -Hot/Wet Multi Gas Analyzer

The 920 is a multi-gas analyzer specifically configured to monitor the stack emissions of multiple pollutants on a concentration basis. Combining hot-wet analysis with reliable ultraviolet-based measurements, the 920 delivers multi-range sulfur dioxide measurements, alongside simultaneous, independent measurements for nitric oxide and nitric dioxide.

A full-function continuous emissions monitoring (CEM) system, the 920 requires the addition of only a sample probe and sample line to be fully operational, and offers automated zero and span calibration.

With a range of housing options, including purpose-built cabinets and walk-in shelters, the 920 provides accurate multi-gas monitoring for pollutants in a range of applications for the hydrocarbon processing and fine chemicals industries.

RELIABLE RESULTS

The UV-based measurements are unaffected by interference from water (H2O) and carbon dioxide (CO2). They also provide a wide dynamic range for some measurements. There is no need for sample drying, which greatly simplifies sample handling and integrity.

HEATED SAMPLE SYSTEM

Sample system components are heated above the dew point of the sample gas. This results in a simpler, more accurate calculation of gas concentrations.

FLOW MANAGEMENT

The analyzer performs all necessary sample gas and calibration gas flow managements, and probe and sample line temperature controls.

The 920 is the UV-based multi-gas CEM system for stack pollutant emissions monitoring on a concentration basis – Find out more.

- Multi-range sulfur dioxide

- Simultaneous NO and NO2 measurements

- Automated zero and span calibration

- Serial communication with plant DCS

Methodology: Multiple wavelength, high resolution, non-dispersive UV

- Optional O2: Integral Zirconium Oxide

- Accuracy:

- +/- 1.0% full scale of standard ranges

- +/- 2.0% full scale of standard ranges for H2S+NH3 application

- Repeatability: Better than 0.5% full scale

- Linearity: Better than 1% full scale

- Response Time: Typically less than 30s to T90 (excludes sample system)

- Number of Gases: Up to 5 simultaneously (refer to AMETEK for possible combinations)

- Sample Transport: Air aspiration

- Typical Sample Flow: 3 to 5 L/min (0.1 to 0.2 CFM)

- Sample Gas Temperature: Ambient to 150°C (302°F)

- Temperature Control: Independent control of three zones (oven, sample line, probe)

- Pressure and Temperature Compensation: Standard

- Ambient Temperature2: 5° to 50°C (41° to 122°F)

- Instrument Air: Minimum 413.6 KPa (60 psig), 120 L/min (4.24 CFM), instrument quality air

- Power: 120 VAC ±10%, 47-63 Hz or 220 VAC ±10%, 47-63 Hz, 600 W for analyzer only

Communications

- Analog: 4 x 4-to-20 mA self-powered

- Digital: One RS232 port for service diagnostics

- One RS422 with Modbus protocol

- Relays: 3 independent sets of SPDT relays alarm conditions

- Physical Dimensions: 1553.6 x 1117.6 x 306 mm (61.17 x 44 x 12 in.)

- Weight: Estimated minimum 160 kg (350 lbs)

- Approvals and Certifications:

- NEC/CEC Class I, Division 2, Groups C & D

- ATEX II 2G EEx pd IIB T3

- Russian Ex Proof Certification; 1ExpydIIBT3

- Russian Gosstandard Pattern Approval

- Complies with all relevant European Directives

1. Accuracy may vary on some applications where multispecies measurement is required.

2. Temperature drift is approximately 1 ppm/°C for the species listed. To achieve maximum accuracy and stability, you can either install the analyzer in a temperature-controlled environment or zero the analyzer more frequently.

- NEC/CEC Class I, Division 2, Groups C & D

- ATEX II 2G EEx pd IIB T3

- Russian Ex Proof Certification; 1ExpydIIBT3

- Russian Gosstandard Pattern Approval

- Complies with all relevant European Directives

- Sulfur Plants

- Smelters

- Power Plants

- Industrial Boilers

- Process Heaters