Aqua-Swirl - Stormwater Treatment System

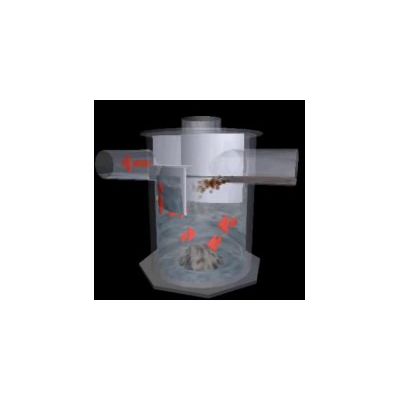

Aqua-Swirl Stormwater Treatment System is a custom engineered, post-construction flow-through water quality device designed to remove coarse sediment, debris and free floating oil by utilizing hydrodynamic separation technology. Aqua-Swirl™ technology is a modular high flow rate treatment system that has no moving parts and operates under gravity flow conditions within a single swirl chamber.

Aqua-Swirl® systems are available in various models based on stormwater performance requirements:

All Aqua-Swirl® models are manufactured from lightweight high performance construction materials depending on project-specific location and needs.

The small footprint design combined with these lightweight and durable materials, eliminates the need for heavy lifting equipment during installation.

Each unit includes lifting supports and stub-outs for the inlet and outlet piping to allow for quick and simple connection to the conveyance storm pipe. Traffic rated manhole frame & cover.

Inspection and maintenance activities are easily performed from the surface without the need for confined space entry or special equipment. A vacuum truck is typically used to clean the swirl chamber.

There are 3 distinct models of the Aqua-Swirl® Hydrodynamic Separator (HDS). Each HDS is designed to provide a high level of water quality treatment through the use of a single swirl chamber. Operation begins when stormwater enters the Aqua-Swirl® by means of its tangential inlet pipe thereby inducing a circular (swirl or vortex) flow pattern. The internal area of each swirl chamber represents the effective treatment area of the device where both the capture and retention of sediment, debris and free floating oil can occur. A combination of gravitational and hydrodynamic drag forces results in solids dropping out of the flow. Particles settle and migrate to the center of the swirl chamber floor where velocities are the lowest. The captured (settled) particles are retained in a cone shaped sediment pile at the base of the swirl chamber. We have outlined specific differences between the models below:

The inline (online) configuration uses an internal bypass (BYP) design to provide full treatment for the most contaminated first flush, while the cleaner peak storm flow is diverted and channeled through the main conveyance pipe.

The BYP design can be compatible with retrofit applications. Local stormwater guidelines should be reviewed to determine whether a BYP system can be used in lieu of an offline water quality treatment unit.

Operation begins when stormwater enters the swirl chamber by means of its tangential inlet pipe thereby inducing a circular (swirl or vortex) flow pattern. The swirl chamber diameter represents the effective treatment area of the device. Both sediment capture and sediment storage is accomplished within the single swirl chamber. A combination of gravitational and hydrodynamic drag forces results in solids dropping out of the flow and migrating to the base of the swirl chamber where velocities are the lowest.

The treated flow exits the Aqua-Swirl® XCelerator behind the arched inner baffle and through an outlet structure positioned at the effluent outlet pipe opening. The outlet structure controls the flow of treated water out of the treatment chamber and is sized to the maximum treatment flow rate (MTFR) of the system. The baffle has a high flow bypass weir which allows flows in excess of the MTFR to spill over it and continue to the outlet structure without passing through the vortex area. Thus, internal bypass flow volumes that exceed the MTFR never co-mingle with the flow volume representative of the effective treatment area.

A unique quality of the Aqua-Swirl® trash capture device is its modular design which allows for faster and simpler installation on new construction or retrofit projects for existing storm drainage structures. No external driving head is needed for operation other than that needed to convey stormwater flow according to the site drainage design. The invert of the inlet and outlet pipe of the Aqua-Swirl® is positioned at the same elevation so that the unit can easily be connected directly to the existing storm conveyance drainage system.