Baioni - Model BaiDec -Horizontal Centrifuge Decanter

The Centrifuge DECANTER works on the principle of the difference in specific weights between the various materials to separate. Solid particles in suspension in a liquid tend to go down because of the force of gravity. With the decanter, it is possible to reproduce and enhance this process inside a cylinder which rotates at high speed to increase the force of gravity in proportion to the speed, therefore making the separation process almost instantaneous.

Separation

The principle of separation of a centrifuge lays on the different specific weights of the materials to be processed. Suspended sodium particles in a liquid tend to fall because of gravity. By using a decanter at a high speed, the separation process is played within a bowl able to multiply the gravity and make the separation almost instantaneous.

Wear Protection

The strong point of the BAIDEC series decanters is certainly the development of solutions able to prevent or delay the wear of their critical parts. Purposely-designed components and antiwear materials are employed for those parts directly in contact with the product to be processed and an additional tungsten carbide coating can ensure an almost unlimited life to the scroll.

Design

The highly specific design of our centrifuges is the result of a study carried out by our R&D department. The main features in this study are the reliability, lastingness, handiness which have been successfully proved before in the mineral field. The use of AIONI decanters is the cost effective solution to the issue of separation, selection, thickening and dewatering.

Efficiency

The gear drive is carried out by two electric motors suitable to vary the differential speed between scroll and bowl and give the machine the best performance. It is for this reason that the BAIDEC series decanters prove to be: practical, as no extra devices need to be added; convenient, as there is a recovery of energy through the connection to the inverter; evironment-friendly as the outflow of liquids do not have to be further disposed.

Control

In order to ease the application of the centrifuges in organic sludge treatments, a PLC system has been introduced to allow both the control of the whole dehydration station and of the centrifuge specifically, depending on the kind of sludge to be processed. Such a control can be carried out by means of a touch screen display placed on the control panel or in remote, from any suitable workstation.

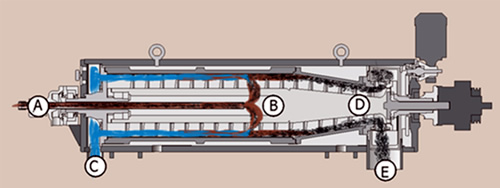

Bowl

The bowl has a conical shape and is in stainless steel to ensure optimal strengh and corrosion resistance.

Scroll

The scroll, in stainless steel, rotates at a slightly different speed than the bowl and conveys the deposited solids toward the conical end of the bowl. This differential speed determines the residence time of the solids in the bowl. Residence time is an important variable for the dry solids content It can be adjusted by changing the differential speed of the scroll thus providing optimal separation. Besides that, by changing the level disks, it is possible to adjust the composition of solids and liquids: a lower level, i.e. when the liquid outlet closer to the machine rotation axis, will allow to obtain an excellent clarified product and a high output at the expense of a more humid solid; a higher level, by adjusting the outlet away from the rotation axis, will guarantee a drier cake at the expense of a cloudy liquid, as the drying area is wider Settled solids are ejected through ports at the conical end of the bowl into the solids housing and fall on a screw conveyor or a belt.

Rotor Bearings

BAIONIoffers a special selection and arrangement of bearings to provide long life and reliability A central lubrication system supplies grease to bearings.

Overflow Weirs

The clarified liquids flow to the cylindrical end of the bowl where they exit over weir plates. Easily adjustable precision weir plates allow for the precise adjustment of the pond depth in the bowl. Overflow is then collected in a centrate chamber and discharged by gravity.

A - Inlet product to separated

B - Liquid-solid separation

C - Dicharge of liquids

D - Dehydration of solids

E - Dicharge of solids

- Treatment of sludge from mineral processes

- Treatment of sludge from sewage depuration plants

- Treatment of sewage from agro-industrial processes

- Treatment of sewage from industrial processes

- Treatment of breeding wastewater

- Treatment of extraction and refining of oils, proteins, animal fat