- Home

- Companies

- Digital Analysis Corp.

- Products

- batchTREAT - Model BT125 - pH ...

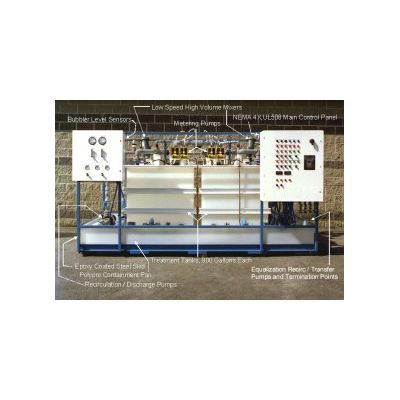

batchTREAT - Model BT125 -pH Neutralization Systems

batchTREAT pH Adjustment systems are designed to handle a variety of highly acidic and highly alkaline waste streams. Any acidic or alkaline stream generated can be neutralized with a batchTREAT pH adjustment system. The BT125 displayed here is capable of treating flows up to 125 gpm, average flow. This family of pH adjustment systems can handle flows up to 1,000 gpm. Although actual throughput is a function of water chemistry. The pHASE family of pH Adjustment systems all utilize our proprietary "Optimized Batch" pH adjustment technology. These systems are well suited for effluent flows of highly acidic or highly alkaline effluents, although they can be utilized for effluent chemistries of any nature.

Influent Characteristics: Flow 0-250 GPM, 125 GPM Nominal Flow. Influent pH 0-14 pH units. Temperature 32-140 F. High solids loading with abrasives.

Effluent Characteristics: Flow, Discharged in batch volumes of up to 800 gallons / batch / system at flows up to 350 gpm / system. pH Nominal discharge range is 6.50 - 8.50 pH units. (Actual discharge limit is field programmable).

Effluent Monitoring: As mandated by the local controlling authority the effluent quality must be continuously monitored. A two pen recorder is to be used to monitor effluent flow rate and pH. The recorder is to be equipped with a flow totalizer. Any effluent pH deviations will trigger an alarm and system discharge will be halted.

The system is supplied as a completely fabricated "turnkey" package. Therefore all devices are wired and plumbed upon shipping. There is a single electrical connection point for incoming power, no further terminations are required. The disconnect on the MCP provides OSHA Lock Out / Tag Out and NFPA 79 compliance. Likewise for air, only one termination point is provided and required and a valve is supplied for OSHA LOTO.. The actual air flow requirements are quite low.

Electrical: 480VAC, 3phase, 60hz, 30 amp. Disconnect not required, provided on MCP.

Air: Less than 1 SCFM @ 80 PSIG. No special requirements for air quality.

Dimensions: 8" x 16" x 8"(h). Access to the front of the skid and the both sides is required for ease of service.

Weight: Approx. 3,800 lbs. dry. (not inc. shipping crate).

Skid: A steel skid is provided for supporting the entire system. The skid features a welded 4" Steel "C" channel frame, a 1/4" steel deck plate, and a 1-1/2" box tube frame. Pipe and conduit supports are provided by heavy duty kindorf rails. The entire skid is bead blasted, primed, and coated with a 2 part epoxy finish for corrosion resistance. The skid color is normally OSHA Safety Blue unless otherwise specified.

Containment Pan: A Polypropylene (PP) containment / drip pan is provided for insulating the steel skid from leaking or spilled corrosive fluids and for containment of leaks. A floor drain is provided for draining the containment pan to a sump. The pan is fabricated from 1/2" PP and features 12" high walls.

Treatment Tank: The treatment tanks are custom fabricated PP tanks with 3/4" walls, and 3/4" base and cover, with a volume of 800 gallons (nominal 650 gals.) each. The tanks are supplied with a 2" gasketed lip for sealing the cover. A reinforcement rib around the perimeter of the tanks provides additional wall support. This ribs are fabricated from 3" Steel "C" channel and are epoxy coated and encapsulated in PP. The tanks are designed for fluids with a s.g. of up to 1.9 with a safety factor of 2:1. Destructive burst testing has shown that tanks of this construction often have an ultimate load safety factor exceeding 3:1. If positive ventilation is used the tank is rated to +/- 20" w.c. The tank top is reinforced and gasketed. The top will support all mounted equipment and the weight of one 200lb. man without significant deflection.

Reagent Storage Tanks: Chemicals required for treatment (acid and caustic) are pumped directly from 400 gallon DOT shipping totes. As an alternative chemicals can be pumped from 55 gallon drums as well.

Piping: All recirculation, transfer and discharge lines are fabricated from solvent welded CPVC SCH 80 pipe. Threaded fittings are not used unless absolutely necessary. All reagent delivery lines are flexible PE tube double contained within a clear flexible PVC hose, clamped at each end to seal leaks.

Valves: All ball valves are true union field serviceable valves. All diaphragm valves are flange mounted. Elastomers are EPDM and Teflon except on concentrated acid lines where the elastomers are Viton and / or Teflon.

Electrical: All enclosures are NEMA 4X, where metallic enclosures are used they are provided with epoxy or polyester finishes for corrosion resistance. All conduit is plastic coated where possible. Low voltage 24VDC is used throughout to minimize service personnel exposure to high voltage.

The system is designed as a duplex batch treatment system designed to accept batches ranging in volume from 100 to 1,200 gallons. In order to allow for continuous flow to the system a first stage equalization stage (not shown in the picture) is used. A continuous output bubbler level sensor is used in both treatment tanks. A Programmable Logic Controller (PLC) within the Main Control Panel (MCP) monitors the equalization tank level. When the level rises above the 40% full mark a pair of transfer pumps are started. If the treatment tank is empty the equalization system automatically transfers a batch of up to 1,200 gallons (if it is available) to the treatment tanks. Once the treatment tanks fill to the high level the transfer from the equalization tank stops. The treatment tanks then treats the tank contents using "Optimized Batch Treatment" technology developed by Digital Analysis. For additional information on "Optimization Technology" contact us and request our technical brief on this subject. Once the treatment tanks contents are within the acceptable discharge range and meet all discharge criteria then discharge commences. When the treatment tanks descends to the 10% full level transfer from the first stage equalization resumes and the process repeats. Each system operates independently of one another. One tank can be filling while the other is treating and discharging. Or, both can be filling at the same time. One system can be shut down completely for service while the other continues to run.

On most systems a pretreatment option is provided for the equalization tank. This option allows for coarse treatment of the equalization tank contents when highly acidic or alkaline materials are present.

A system of this design architecture is very versatile in that it can handle large flows when the influent chemistry is mild and can handle very concentrated effluent streams and accidental spills. This system is normally used in applications that can see widely varying flows and widely varying influent chemistries. For flows from 1GPM up to 60 GPM our prepackaged pHASE line of equipment usually perform just fine. For higher flows, or effluent streams with the potential of high volume, highly concentrated discharges then a custom fabricated system as depicted here is required. Flows up to 200 GPM can be handled with skidded systems such as this unit.

For specific equipment information contact us directly. We can provide the specifying engineer with a formatted specification package that thoroughly describes any of our systems for bidding purposes. This includes detailed drawings, and detailed equipment specifications.