- Home

- Companies

- Jiangxi Aite Mass Transfer Technology ...

- Products

- AITE - Ceramic Corrugated Plate Packing

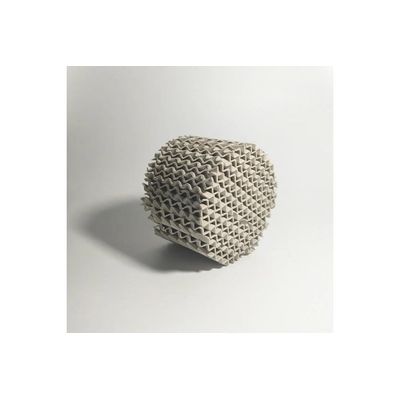

AITE - Ceramic Corrugated Plate Packing

It is constructed of corrugated sheets of ceramic.The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, form mixing cells at every point where the corrugation intersect.High temperature and corrosion resistance Ceramic Corrugated plate packing

Owing to ceramic surface has good hydrophilic, it can enlarge to gas-liquid contacting surface area. Meanwhile, ceramic surface’s microporous structure also improve wettability and generate extremely thin liquid film. Turbulent liquid flow and tortuous vapor flow passages promote mixing of liquid and vapor with a low pressure drop. This is why ceramic Corrugated plate packing has same mass transfer efficiency same as metal packing. Furthermore, Resistant to corrosion and high temperature performance is excellent than other material packing.

In addition, ceramic excellent corrosion resistance makes Ceramic Corrugated plate packing more suitable for sulfuric acid absorption, the nitrate concentration,gas purification and so on. Ceramic high thermal stability make its operating temperature exceeds 1000 ?

- Sulfuric Acid Plant

- Regenerative Thermal Oxidizers

- Chlorine Cooling and Drying Towers

- Bromine and Hydrochloric Acid Plant

- Liquid Organic Waste Disposal Coolers and Scrubbers

- Natural Gas Treating and Dehydration units

- Purification of Aqueous Organic Acids.

- Excellent surface wetting ability, larger mass transfer area, and higher separation efficiency,

- High compressive strength;

- Available specific surface area between 64m²/m³ and 500m²/m³;

- Little magnifying effect;

- More fields/conditions to be applicable.