- Home

- Companies

- AMSA, Inc.

- Products

- AMSA BCP - Model Classic DTEA II - ...

AMSA BCP - Model Classic DTEA II -Chemical Cooling Water Systems 1000 Series

AMSA BCP 1000 series is the classic DTEA II chemistry that has been used for over 20 years to clean up cooling water systems and maintain clean surfaces in those systems! BCP 1015 is the flagship DTEA II that penetrates, disperses and cleans organic deposits in industrial process cooling systems and commercial and residential building comfort cooling systems. It is especially useful in systems that re-use wastewater.

BCP Chemistry - Products Overview

AMSA, Inc. chemistry brings many benefits to cooling water treatment programs.

All AMSA BCP products are designed to improve water treatment programs so these programs sustain clean surfaces and maintain biological control. When AMSA BCP chemistry is used in conjunction with a biocide, the resulting treatment program is a superior biofilm/algae/legionella control program.

Key Features of the BCP 1000 series - a truly multipurpose chemistry

Penetrates, disperses & cleans organic deposits

- Cleans fouled systems and keeps them clean

- Results in clean equipment & piping surfaces

Benefits of deposit-free surfaces:

- Less susceptible to microbially induced corrosion

- More efficient heat transfer on exchanger surfaces

- More efficient evaporation in the cooling tower fill

- Less likely to harbor pathogens such as Legionella

- More accessible to corrosion and scale inhibitors

- Outward appearance of cooling tower is more attractive to facilities management

Inhibits yellow metal corrosion

- Enhance standard azole programs

Reduces use of biocides

- Helps biocides (oxidizing and non-oxidizing) work more efficiently

Enables operation at higher cycles of concentration

- Effectively disperses solids to maintain clean surfaces under high TDS and TSS condition

Effective in the presence of ammonia and hydrogen sulfide

- Allows use in refinery cooling systems and systems using wastewater as make-up

Readily biodegradable

- Rapidly degraded by native microbial populations when released at typical discharge concentrations into open natural environments

Stable in closed systems

- Stable for many months at concentrations typically used in closed loop systems

- Rapidly degraded by native microbial populations when released at typical discharge concentrations into open natural environments

BCP 1015 is used to clean up fouled systems. When used as a part of a regular maintenance dosing program in conjunction with other industrial water treatment chemicals, surfaces are kept clean.

In addition to the cleaning, dispersion, and other multi-functional features of all BCP products, BCP 1015 special features include:

Compatible with biocides* at end use levels

- Helps biocides (oxidizing and non-oxidizing) work more efficiently

Works well in continuous feeding programs with oxidizers

- BCP 1015 can be fed at low doses continuously with oxidizing biocides

Contributes no nutrients which will support microbial/algal growth

- Fully water soluble and does not require additional biodegradable organic solvents

- Contain no phosphorus, therefore does not support algal growth

Sold in concentrated formulas

- BCP 1030 and BCP 1100 are concentrated formulas containing DTEA II.

*For more information on using BCP 1015 with glutaraldehyde.

BCP 1000 series industrial water treatment chemicals are an essential part of a Biofilm Control Program

BCP 1015 is the classic DTEA II-based biofilm control program chemistry used by water treatment professionals since 1999. This standard formulation is compatible with most common water treatment chemicals and biocides. Combining BCP 1015, or other BCP products, with the action of oxidizing and non-oxidizing biocides delivers an effective Biofilm Control Program.

BCP 1030 is a special formulation designed for large systems and overseas use.

BCP 1100 is sold as a manufacturing use product for formulation.

BCP 1015 (DTEA II) brings many benefits to cooling water treatment programs.

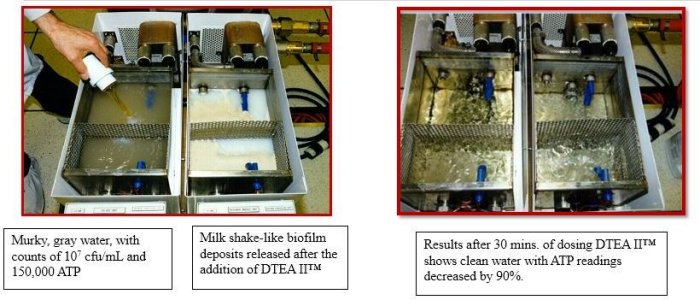

AMSA customers have used BCP 1015 to clean fouled systems and maintain clean surfaces in those systems for over 20 years. AMSA cooling tower chemicals and process water chemicals have been a trusted solution to ‘Clean it Up & Keep it Clean’ for many water treatment service companies. Below is one example of a clean-up application using BCP 1015 (DTEA II) in a super computer data center.