EIW - Classifying Tanks for Water Scalping and Sand Separation

Designed to remove large volumes of excess water from feed material, Eagle Water Scalping-Classifying Tanks are typically used in applications such as dredging and pumping, as well as with high silt materials. They smooth out feed fluctuations and are key in removing excess sand particles for a consistent, reliable in-spec product.

Effective and low maintenance, these units accept either slurry or a dry feed. They will handle gradation swings in the average deposit or in a manufactured crushed sand while minimizing waste. The Eagle Water Scalping-Classifying Tank has a large settling area, making it easier to retain fine mesh particles required of a typical concrete sand specification like C-33, and produce secondary and tertiary products such as masonry/mortar, asphalt, golf and other specialty sands.

Spanning the length of the tank is a valve bridge that houses six to 11 valve stations, depending on the length of the tank. Each of these valve stations typically consists of a sensing device and three hydraulic cylinders (for a 3-cell tank) that operate valves at the bottom of the tank. Via an Eagle Iron Works PLC system, the three valves at each station discharge into three separate collecting-blending flumes beneath the Classifying Tank. The flumes, in turn, recombine the fine and coarse sand fractions for each product, channeling them to dewatering equipment beneath the Classifying Tank.

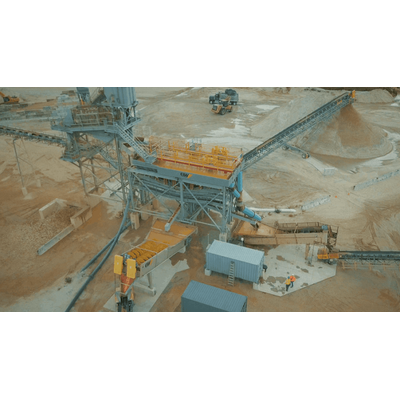

Eagle Iron Works can provide Classifying Tanks in three different configurations – stationary, semi-portable and portable. Stationary tanks allow for high plant customization and ease of maintenance, while requiring a supporting structure. Semi-portable plants are often modular for quick set-up, have a low feed height, and the plant structure and wiring are included; however, there is limited customization of the plant. Portable plants also have reduced options for customization but are built onto a wheeled chassis that can meet DOT standards and can be transported from site to site. They also have a low feed height requirement, and the plant comes pre-wired.