- Home

- Companies

- Trelleborg Forsheda Pipe Seals

- Products

- Trelleborg - Model 589 Din-Lock ...

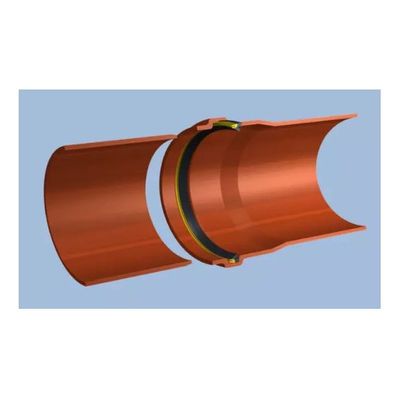

Trelleborg - Model 589 Din-Lock (inches) -Combined Lip and Compression Sealing System

Trelleborg 589 Din-Lock seal is a combined lip and compression sealing system that is positioned in the socket by the pipe manufacturer after the bell has been formed. The unique design has a flexible thermoplastic elastomer sealing element bonded to a polypropylene retaining ring which holds the seal firmly in the correct position during pipe transportation and joint assembly. The seal is designed to absorb any permissible variation in groove geometry whilst maintaining a high sealing performance with the lowest possible jointing force.

- Cannot be displaced during transportation & installation

- Fully fills the groove to prevent dirt intrusion before joint assembly

- TPE-V for increased oil resistance

Trelleborg 589 Din-Lock seal meets or exceeds current American standards for wastewater lines both for indoor and underground. Furthermore, the seal design gives low assembly forces making pipe jointing easier.

On each seal, profile thickness, outer diameter, recommended pipe measurement and production period are given. The corresponding data are also on the packaging.

Subject to change for technical reasons

Step 1

- The spigot and socket of the pipe should be checked for damage prior to jointing.

- The pipe spigot should be chamfered with an angle of 15°, taking care to remove all burrs.

- Both spigot and socket including the sealing ring should be free from dirt and other foreign matter.

- Lubricant should be applied evenly to the spigot end of the pipe.

- Trelleborg 589 Din-Lock seal meets or exceeds current American standards for wastewater lines both for indoor and underground. Furthermore, the seal design gives low assembly forces making pipe jointing easier.