- Home

- Companies

- DAS Environmental Expert GmbH

- Products

- DAS - Model Tilia - Waste Gas Treatment

DAS - Model Tilia -Waste Gas Treatment

TILIA DUO

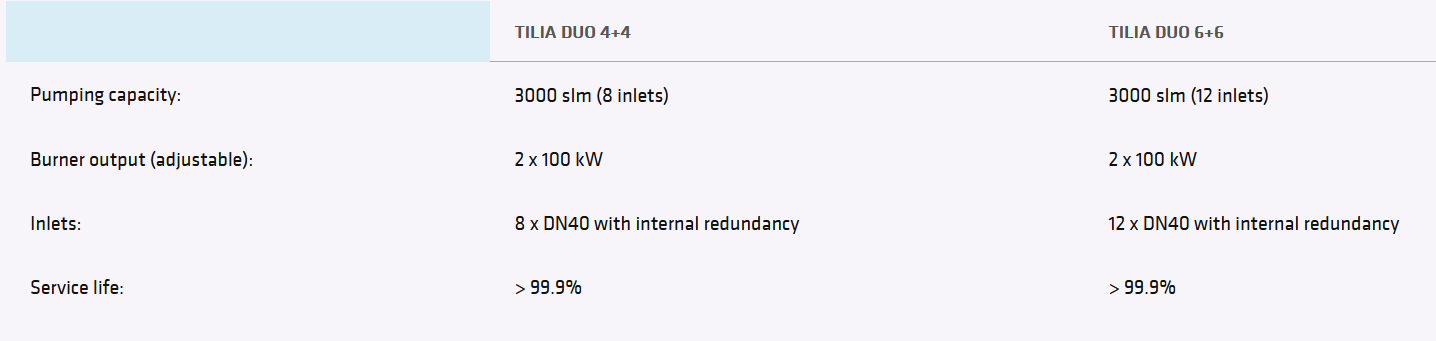

TILIA DUO contains two independent units, each consisting of one combustion reactor and one scrubber with an integrated demister located above it. Each unit also has its own power supply. TILIA DUO is available in the variants TILIA DUO 2+2, TILIA DUO 4+4 and TILIA DUO 6+6. Each unit has 2, 4 or 6 waste gas inlets as well as 2, 4 or 6 additional inlets, which are connected to the other unit via back-up lines. If necessary, the waste gas at the inlets of one of the two units can be diverted to the other unit. As a result, the system has internal redundancy and thus very high availability.

TILIA — for Advanced Etch and CVD Applications

TILIA DUO is designed to efficiently handle the increasing process gas flows and can therefore replace several conventional exhaust gas cleaning systems.

- Burn-/Wet System (Scrubber) with liquid recirculation

- Serves up to 8 or 12 process chambers with up to 2400 slm total flow depending on process

- Best in class capacity per footprint with cost effective integrated backup

- Reactor capacity up to 1200 slm inert gas (per reactor) depending on process

- Implementation of safety requirements of new processes with higher number of process modules, larger process gas flows and higher total flows

- CVD

- Etch (Metall, Poly, Oxides, etc.)

- Epitaxy

- GaN

- MOCVD

- LED