DAS Environmental Expert GmbH

- Home

- Companies

- DAS Environmental Expert GmbH

- Products

- DAS - Model Uptimum - Optimized Waste ...

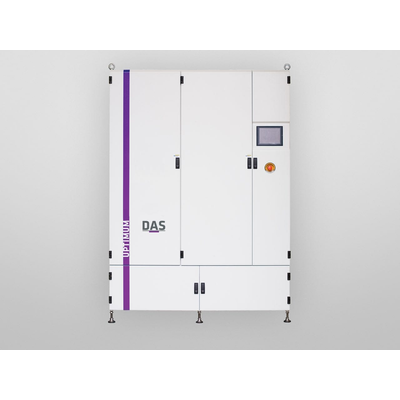

DAS - Model Uptimum -Optimized Waste Gas Treatment System

The UPTIMUM product line has been designed for higher tool uptime especially in CVD processes in the semiconductor and solar industry. The product name UPTIMUM refers to the term “Uptime“ underlining the high availability of the burn/wet system. The tool can be applied to different applications.

Most popular related searches

waste gas treatment

gas treatment

gas treatment system

waste treatment

waste treatment system

air pollution regulations

process waste

pollution regulations

safety can

drip pan

All UPTIMUM systems have a small footprint with service and maintenance access from the front and back. Installation is quick and easy and does not require specialised equipment. Operation costs and general safety can be optimised with a process tool interface.

Process waste gases are induced through a maximum of six separate inlets. Depending on the chemical composition of the waste gases, various reactions take place (oxidation, reduction, pyrolysis). A fluid wall/film prevents corrosion and deposition of particles in the reactor. In the washing column next to the reactor, soluble components are absorbed and particles suspended. The scrubbing liquid cools down and neutralises combustion products such as hydrogen halides. With the application of UPTIMUM within a holistic abatement concepts, manufacturers in the high-tech industry will meet the strict standards of the German air pollution law (TA Luft).

- Runs with different fuel gases

- Low water consumption through closed-loop design

- Dimension (W x D x H): 1525 mm x 1050 mm x 2100 mm

- Access to maintenance area on front and back side

- Gas entry: up to 6 x DN25 or 4 x DN 40

- Gas outlet: max. DN100

The following equipment options are available for all UPTIMUM systems:

- Power Supply: 3 x 400 V/50 Hz or 3 x 208 V/60 Hz

- Fuel Gas: NG, LPG

- Oxidant: O2, CDA

- Closed-loop system: Water, Lye

- Heated feed lines and inlets

- Process-Tool-Interface

- Signal Tower

- Drip Pan

- Earthquake Safety Kit

- Monitoring

- SEMI S2 certification