- Home

- Companies

- S&G Enterprises, Inc.

- Products

- Ram Flat - Model 55ER - Drum Compactor

Ram Flat - Model 55ER -Drum Compactor

Built for medium to heavy duty applications & volume using 55-gallon drums. With a powerful 60,000 pounds of compaction force, the Model 55ER is perfect for inside-the-drum applications like paint filters, rags or low-level. A full 15 inches of clearance above the drum allow operators the ability to load the drums without removing the drum from the compactor. This extra clearance is also important to permit “overfilling” of the drum to maximize the amount of waste compacted on every cycle.

Despite being our “middle of the road” compaction force model, the rolled plate-steel compaction chamber and automatic pushbutton controls are similar as what is used on our continuous-use Model 55AR. As a matter of fact, the 55AR and 55ER have the same pump and high-pressure hydraulic system. The 55ER is truly built to last.

Looking to crush drums, too? Like most of our RAM FLAT Compactors, the 55ER can easily be configured to crush empty drums by adding the optional bolt-on crushing plate. This simple to use add-on attaches an oversized platen to the smaller diameter compaction head allowing you to use one machine for both applications.

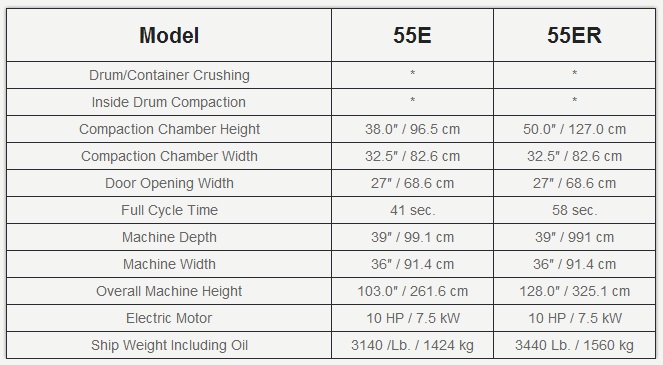

For dedicated 55-gallon drum crushing, check out the little brother of the Model 55ER, the Model 55E. These two models share the same basic construction, controls and hydraulics but the shorter compaction chamber height (38.5 inches tall) allows the 55E to crush a drum to a height of 4.5 inches tall in 40 seconds.

- 60,000 lbs. hydraulic force for inside drum compaction/drum crushing

- 55ER has extra large drum clearance for material overfill

- 5" NFPA cylinder with 3.5" chrome rods

- .188 Steel Plate Crushing Chamber with 1" thick base plate

- 1" Steel Compaction Head with reinforcing gussets

- Positive Displacement Piston Pump for consistent cycle times

- Drum Handling : Move drums to and from the compactor

- Alternate Compaction Head – (CH) : Crush empty drums with the same machine

- Bolt-On Crush Plate- (CP) : For quick changeout between compacting & crushing.

- NEMA 4 Water Tight Enclosures : A must for outside installations

- RAM BOTTOM LOCK Control : Control material springback

- PAK-MORE Hold-down Disk : Improve volume reduction

- Air Filtration and Ventilation : Control dust & vapors

- Liquid Containment : Control spills or leftover residue

- Special Custom Options

Model 55ER

- 10-HP TEFC pump motor

- 115V Electrical Control Circuit automatic pushbutton cycle

- 115V Electric Door Interlock

Model 55ER-P

- 10-HP Class 1, Division 1, Group D explosion-proof pump motor

- Non-sparking pneumatic Control Circuit with Automatic Pushbutton Cycle

- Pneumatic Door Interlock

Model 55ER-HY

- Class 1, Division 1, Group D explosion-proof pump motor

- Non-sparking hydraulic Control Circuit with Automatic Pushbutton Cycle

- Hydraulic Door Interlock