- Home

- Companies

- Duperon Corporation

- Products

- Duperon FlexRake - Model FRHD - Heavy ...

Duperon FlexRake - Model FRHD -Heavy Duty Trash Racks

The workhorse that set the standard for simplicity in unpredictable environments. The FlexRake® Heavy Duty (FRHD) model is a coarse screen engineered for open channel and applications where debris size and velocity may be unpredictable. The FlexRake HDs are the industry’s workhorse. They have proven their versatility with more than 35 years of handling the debris that makes it into a channel – from general refuse, aquatic vegetation, tree limbs, tree branches and shrubs to lumber, tires, oil drums, and automobile frames.

The FlexRake’s level of performance in both daily operations and unpredictable conditions, benefits many other industries. Wherever applied, it is a workhorse that just keeps running, without operator intervention. The inherent value of the FlexRake is its simplicity: long product life, low cost of ownership, and adaptability to a range of site conditions (varied flows, debris types, and volumes). Duperon Corporation is continuously reinventing what is possible for simplicity in screening.

The FlexRake® was invented to offer a simple raking device that solved the challenges of screening open channels, intakes and rivers such as:

- Static trash racks that required workers to manually clean, often in dangerous weather events and hazardous physical conditions

- Unreliable and maintenance-intensive designs

- Long cycle times across intakes that couldn’t keep up during storm or vegetation events when they were needed most

- Submerged sprockets that were subject to fouling, jamming, in-channel maintenance and even required divers to repair

The FRHD has proven a dependable solution in rain or shine. It has withstood seasonal weed blooms and protected communities from hurricane floodwaters. Its reliability and unmatched adaptability translates into everyday pump protection and failsafe performance in events of magnitude.

The FlexRake HD is a front-clean, front-return, mechanically cleaned bar screen. Features the industry-leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake is unhampered by large debris.

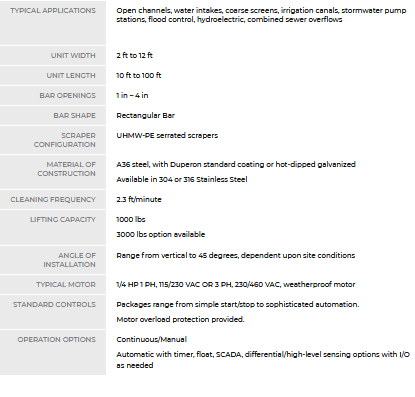

The FlexRake HD is a coarse screen that utilizes A36 steel with Duperon standard coating or hot-dipped galvanized (but is also available in 304 and 316 stainless steel). It has bar opening options from 2 inches to 4 inches. Serrated UHMW-PE scrapers are used to clean the face and in between the bars.

Adapts to a range of unpredictable flow and debris conditions without operator intervention

No in-channel maintenanceWith no lower sprocket, the FlexRake FRHD allows maintenance to be performed from the deck. There are no jam points underwater to require diving or confined space entry for improved worker safety

Reliable operationDesigned for 24/7 operation. Units can stand idle for long periods, yet reliably respond when needed during a storm or debris event

CustomizableEngineered to fit the unique needs of your site

Low cost of ownershipFractional horsepower, few parts, minimal maintenance; the FlexRake HD is easy to install, own, and operate by your own crew

Uninterrupted water flowContinually cleans across entire intake with multiple scrapers to avoid blinding and to limit headloss to ensure water is kept moving

Wildlife-friendlyThe FlexRake HD received Manatee Safe designation from the US Army Corps of Engineers (USACE), US Fish & Wildlife Services (FWS) and Florida Fish and Wildlife Conservation Commission (FWC)

- Open channels

- Water intakes

- Coarse screens

- Stormwater

- Irrigation canals

- Pump stations

- Flood control

- Hydroelectric

- Drainage canals

- Combined sewer overflows

- Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

- FlexLink™ multifunctional link system has ultimate strength of 60,000 lbs with unmatched durability

- Jam Evasion™ technology lifts and pivots around debris to remove from channel without shutdown or jamming

- Swinging drivehead allows the entire raking system to move outward to discharge large debris

- Full-Screen Cleaning™ reduces the risk of blinding at the intake by cleaning all of the screen all of the time

- Fractional horsepower motors used for energy efficiency

- Everything is serviceable from the deck to eliminate in-channel maintenance and confined space entries