- Home

- Companies

- Environmental Dynamics International ...

- Products

- EDI - Silicone Membrane Material

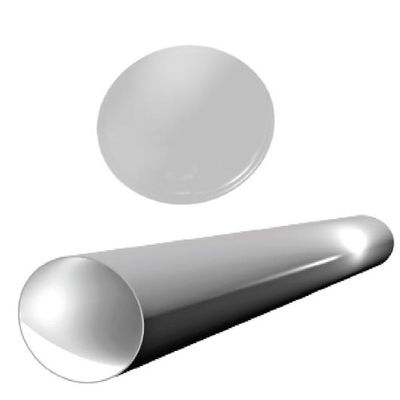

EDI - Silicone Membrane Material

Material Features: High temperature resistance up to 350 °F (177 °C). Excellent uniformity and distribution of released air bubbles. Formulated for application specific condition. Good chemical compatibility in most municipal and industrial application. Available for tube and disc diffusers. UV protection inherent in the compound. Low dynamic wet pressure (DWP). Note: Not recommended for some ON/OFF applications.

Most popular related searches

material properties testing

material testing

wastewater treatment membrane

hardness testing

disc diffuser

wastewater treatment

ozonation

wastewater membrane

membrane wastewater treatment

membrane treatment

- Hardness Shore A: 60 +/-5

- Specific Gravity: <1.25

- Tensile Strength, psi: >9.0 MPa

- Tensile Modulus, @100% elongation: 2.69 +/- 0.28 MPa

- Ultimate Elongation: > 400%

- Tear Strength, Die T: >10.5 kN/m

- Surface Ozone Cracking Resistance @50 ppm: Non Cracking

- Low Temperature @ -40°C: Non Brittle

- Hardness Shore A: 60 +/-5

- Specific Gravity: < 1.25

- Tensile Strength, psi: > 1300 psi

- Tensile Modulus, @100% elongation: 390 +/-40 psi

- Ultimate Elongation: > 400%

- Tear Strength, Die T: >60 lbf/in

- Surface Ozone Cracking Resistance @50 ppm: Non Cracking

- Low Temperature @ -40°C: Non Brittle

- Hardness Shore A: 58 +/- 5

- Specific Gravity: < 1.20

- Tensile Strength, psi: > 7.9 MPa

- Tensile Modulus, @100% elongation: 1.38 +/- 0.34 MPa

- Ultimate Elongation: > 600%

- Tear Strength, Die T: >12 kN/m

- Surface Ozone Cracking Resistance @50 ppm: Non Cracking

- Low Temperature @ -40°C: Non Brittle

- Hardness Shore A: 58 +/-5

- Specific Gravity: < 1.20

- Tensile Strength, psi: >1150 psi

- Tensile Modulus, @100% elongation: > 225 psi

- Ultimate Elongation: > 600%

- Tear Strength, Die T: >70 lbf/in

- Surface Ozone Cracking Resistance @50 ppm: Non Cracking

- Low Temperature @ -40°C: Non Brittle