- Home

- Companies

- Junker-Filter GmbH

- Products

- ZERO - Filter Bag

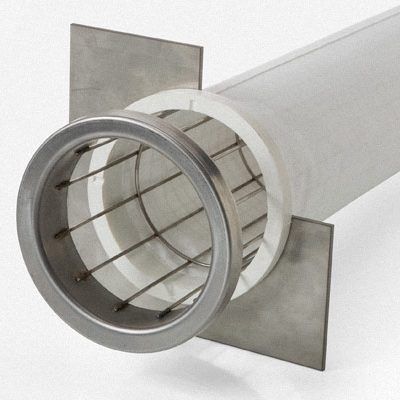

ZERO - Filter Bag

In order to be able to meet the steadily increasing requirements for emission limit values, innovative solutions are required. With the innovative ZERO ® design, Junker-Filter relies uncompromisingly on quality and “zero” emissions. On the basis of the highest quality filter media, we achieve this goal through first-class assembly without any seams or needle holes.

The advantages of our ZERO design:

- cast head / base design without stitched seam holes

- prevention of fibre migration through thermally sealed cut edges

- suitable for contact with food including certification according to FDA and EU 10/2011

- no contamination from sewing thread residues; optimal conditions for the pharmaceutical / food industry

- 100% sealing through total snug fit

- reduced emission values

- can be used with high-performance filter media and special casting compound for a wide variety of applications

- available in different designs and dimensions

On July 7, 2015, Environment Minister Franz Untersteller awarded the state’s environmental technology prize for innovative technologies in the field of resource conservation in industrial production processes and procedures. Junker-Filter GmbH convinced the jury in the category “Emission Reduction, Treatment and Separation” and received 1st place:

Thanks to our innovative assambly, we can significantly reduce the amount of fine dust in the exhaust air. For this purpose, filters without a seam were developed, as the needle punctures lead to permeability and a 20 times higher clean gas dust content of fine dust. At the same time, our new design prevents cross contamination from e.g. Prevents fiber abrasion or thread residues, whereby a very high quality of the end product can be achieved. This also increases the end customer’s resource efficiency.

- polyester

- polypropylene

- polyacrylnitrile

- polyamide

- singed

- calandered

- siliconized

- oil and water repellent effect

- PTFE coating

- laminated PTFE membrane

- antistatic

- microfibres

- asymmetric structure

- etc.

- food industry

- chemical industry

- pharmaceutical industry

- plastics industry

- wood industry

- metallurgy

- energie

- quarry and pit industry

- etc.

- without seams and needle holes

- 100% sealing through total snug fit

- FDA-/ EU10/2011 conformity

- reduced emission values