- Home

- Companies

- InduMar Products, Inc.

- Products

- InduMar - Flat Patch Tank Repair Kit

InduMar - Flat Patch Tank Repair Kit

The Flat Patch Tank Repair Kit is a carbon-epoxy composite repair system designed for active sealing applications where localized repair is needed or full pipe wraps are impractical. The system combines a preformed carbon sheet with advanced adhesives to enable working pressures up to 1,000 PSI (70 kg/cm2) and operating temperatures upto350°F(177°C).

The Flat Patch Tank Repair Kit consists of a preformed carbon composite sheet and two advanced epoxy adhesives to provide superior leak sealing on flat surfaces. This novel approach enables the sealing of actively leaking defects, the localized repair of tank surfaces, and the ability to bond through oil contamination. The repair kit is recommended for pressure applications up to 1,000 psi (70 kg/cm2} with a built in 4:1 safety margin. Return to service at pressure may be accomplished in ~2 hours for temperatures above 75°F.

Flat Patch Tank Repair Kit Attributes

- Adaptable composite construction paired with time-efficient installation methods addresses a wide range of tank sizes

- Advanced adhesives eliminate leaks without the need to drain the tank

- Cartridge dispensing minimizes waste, ensures complete mixing, and manages pot life

- Short cure time allows rapid repair and reduced time on site

- Outstanding compressive, flexural, and adhesive bond strength

- Accelerated cure times are possible with annealing of the installed repair

- Carbon fiber composite repair system safely and quickly restores operations up to 1,000 psi, and provides localized corrosion inhibition

Flat Patch Tank Repair Kit Specifications

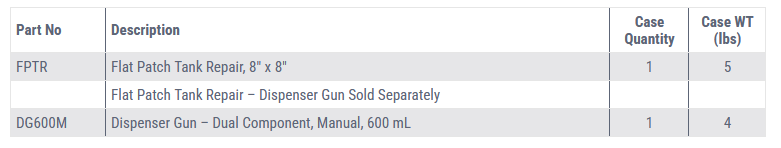

- Packaging: Primary resin supplied in the form of a two-part putty. Secondary resin supplied in dual cartridge with pre-measured volumes sized. Kits provided with static mixers, spreaders, and gloves. Two-part dispensing guns sold separately.

- Sizes: Patch size- 8" x 8"

- Shelf Life: Part A: 12 months at 75°F (24°C). Part B: 12 months at 75°F (24°C)

- Storage Temperature: 32 to 100°F (0 to 38°C), 0-100% relative humidity

- Application Temperature: 50 to 150°F (10 to 65°C)

- Surface Preparation: Surfaces must be freed of any loose scale or debris. If possible, remove other surface coatings before application.

Shelf Life: 12 months when stored @ 55ºF to 75°F (12°C to 24°C)

Physical Form: Two-part, solvent-free resin system

Mixing Ratio: 1:1

Working Time: 6–8 minutes

Mixed Viscosity: 50,000 cps

Application Thickness: <0.02”

Coverage: Each 50 mL cartridge coats 250 in² at the recommended thickness; 400 mL cartridge coats ~2000 in²

Water Resistance: High

Chemical Resistance: Very Good