Filtration Solutions Inc.

- Home

- Companies

- Filtration Solutions Inc.

- Products

- FSI - Model FRS - Fuel Recycling System

FSI - Model FRS -Fuel Recycling System

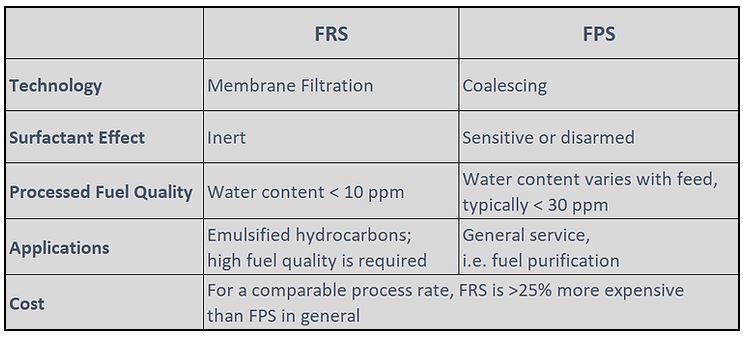

FSI uses membrane filtration to separate water from hydrocarbons (fuels/solvents). By taking advantage of the fact that water forms beads in hydrocarbons (due to higher surface tension of water compared to hydrocarbons), a membrane with a properly designed pore size will separate water beads.

Most popular related searches

spiral wound membrane

filter element

depth filter

recycling separation

recycling separator

spiral wound

membrane filtration

water filter element

recycling system

waste recovery

- The Water Selective Membranes from FSI have an optimized pore size and surface properties that can resist high water breakthrough pressure to provide an exceptional water separation efficiency.

- FSI`s FRS systems (with processing capacities from 2 gallons to over 50 gallons per minute) are designed to remove debris and water from various fuels. The products have been used in the US Army, the US Navy, air-derivative gas turbines, and for waste fuel recovery from junk yards.

- FSI`s water-selective filter elements simplify the two-stage filtration and separation process into a one-stage process.

- The approach makes use of cross-flow, which is a surface filtration technique that minimizes the build up of the membrane surface cake layer and eliminates the passage blockage encountered when depth filtering is subjected to dry conditions.

- In addition, the filter element takes advantage of a spiral-wound membrane cartridge design that maximizes filtrate flow capacity for a given volume to facilitate high capacity applications.

- Aviation fuels: commercial Jet A, Jet B, and Jet A-1, military JP-4, JP-5, and JP-8 with additives

- Vehicle/commercial fuels: diesel, gasoline, and kerosene

- Hydrocarbon solvent purification and recycling

- Separation of emulsified water/fuel and water/solvent mixtures

- Purification of oil refinery products