- Home

- Companies

- Duperon Corporation

- Products

- Duperon FlexRake - Model FPFS - Full ...

Duperon FlexRake - Model FPFS -Full Penetration Fine Screen

The workhorse that set the standard for simplicity in fine screening in the water and wastewater industry. The FlexRake® Full Penetration Fine Screen (FPFS) model offers multi-rake fine screening for openings ¼ inch to ½ inch. It combines rugged adaptive technology from the FlexRake’s flood control origins and is specifically engineered to manage sticky or difficult-to-capture debris, making it ideal for wastewater and industrial applications.

The FlexRake FPFS has been installed in hundreds of sites in a variety of applications. Wherever applied, it is a workhorse that just keeps running and optimizing downstream process and equipment performance. The inherent value of the FlexRake is its simplicity: long product life, low cost of ownership, and adaptability to a range of site conditions (varied flows, debris types, and volumes).

Duperon Corporation continues to reinvent what is possible for simplicity in screening. Imagine what’s next.

The FlexRake® FPFS is a front-clean, front-return, mechanically cleaned bar screen. Features the industry-leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake® is unhampered by large debris.

The FlexRake® FPFS is a fine screen that utilizes individually replaceable, stainless steel, tear-drop shaped bars with ¼ inch to ½ inch openings. Stainless steel Thru-Bar™ scrapers eliminate accumulation by cleaning all three sides of the bar and cross members to remove hard-to-capture-debris.

High capture rate and efficient hydrodynamics allow for more favorable flow conditions and less headloss

Flexible designAdapts to a range of unpredictable flow and debris conditions without operator intervention

Process resilienceEffective fine solids removal through a broad range of flow and debris conditions so downstream assets remain protected

Reliable operationThe FlexRake FPFS adapts to handles grease, grit, first flushes, rags, large or unusual debris (2×4’s, bricks or sewer plugs) without shutdown or operator intervention

Low cost of ownershipWith few parts and minimal maintenance required, Duperon equipment is easy to install, own, and operate

No in-channel maintenanceEverything is serviceable from the deck, eliminating confined space entries, jamming and routine in-channel maintenance

CustomizableEngineered to fit the unique needs of your site

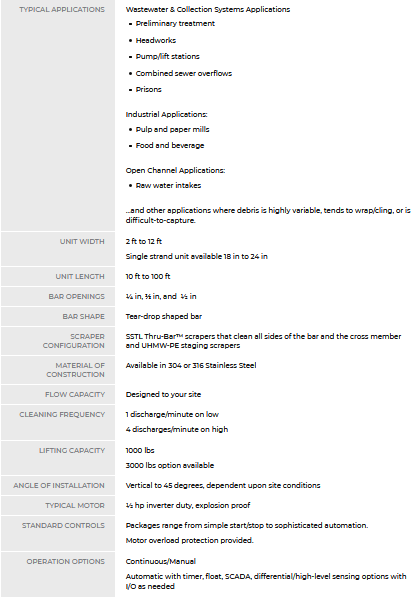

Wastewater & Collection Systems Applications:

- Preliminary treatment

- Headworks

- Pump stations

- Lift stations

- Combined sewer overflows

- Prisons

Industrial Applications:

- Pulp and paper mills

- Food and beverage

Open Channel Applications:

- Raw water intakes

- And other applications where debris is highly variable or difficult-to-capture.

- Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

- FlexLink multifunctional link system has ultimate strength of 60,000 lbs with unmatched durability

- Full-Range Flexibility adapts to debris variations; from grit and grease to hard hats and sewer plugs

- Jam-Evasion™ Technology lifts or pivots to process large debris without shutdown or jamming

- Tear-drop shaped bars are the most efficient on the market and allow for more favorable flow characteristics and less headloss

- High-capture Thru-Bar™ cleaning cleans all three sides of the bar and the cross member

- Fractional horsepower motors used for energy efficiency

- 5 year warranty for wastewater applications

- Everything is serviceable from the deck to eliminate in-channel maintenance and confined space entries