- Home

- Companies

- DJE Recycling Systems Limited

- Products

- DJE - Model RPC66120 - RPC66160 - ...

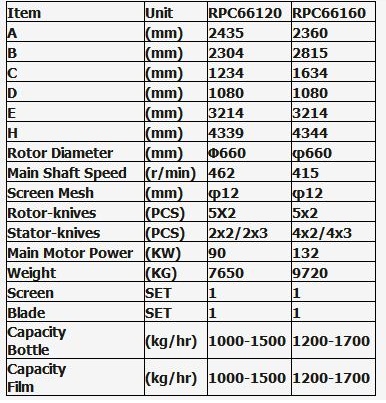

DJE - Model RPC66120 - RPC66160 -Heavy Duty Granulators 1000 - 1700 Kgs Hour

Heavy Duty RPC66120 - RPC66160 Granulators, suitable for crushing - granulating very large plastic products between capable of granulating 1000 - 1700 Kgs Hour depending on the materials. Welded by rigid steel structure, which are specifically designed to meet the needs to the difficult-crushing recycling materials, and suitable for crushing pipe, film, sheeting and large-size solid materials. The rigid welded steel structure is designed to withstand the most extreme grades of plastic materials and ensures consistent performance and long lasting service.

- Lump/Purgings

- Films

- Pipes

- Woven bags

- Plastic containers (IBC`s, HMHD blue drums,)

- WEE derived plastics

- Cable

- Non plastics materials such as wood, metal containers and cardboard.

Special blade fitting for hard, normal, soft and thin material. Steel structured box, cast steel knife holder, and high quality tooling steel knife are all firmly fastened with high-strength steel screws for long service.

- Built using D2 Steel

- Siemens motors used throughout

- Microcomputer technology incorporating rotator speed variations with start, stop and reverse features.

- Automatic reverse sensors to protect the machine against over loading and jamming.

- Engineered using split bearing block technology so the blades can be changed quickly and efficiently.

- Specifically designed rotor to be extremely wear resistant.

- Rotor teeth can be rotated 4 times maximising the life span of a single set resulting in minimum down time spent.

- Extremely versatile machine able to process a number of different materials.

- Comprehensive set of spare parts and screens so suit specific requirements.