- Home

- Companies

- Tenmat ltd

- Products

- Tenmat Firefly - Hot Gas Filters

Tenmat Firefly - Hot Gas Filters

Tenmat Firefly Hot Gas Filters are designed to remove particles, acids, heavy metals and dioxins from the flue gases at temperatures higher than those achievable with any conventional system. The filter elements are manufactured from unique refractory materials and inorganic bonds, enabling them to be used at temperatures in excess of 1,000°C. TENMAT manufactures a wide range of filter media designs, seals and insulation that can be tailor-made to customer requirements.

FIREFLY HOT GAS FILTERS are rigid surface filters developed for operating temperatures in excess of those achievable by existing fabric filters.

TENMAT elements are self supporting, therefore do not require metal cages allowing their usage in corrosive environments.

CS1150F filters possess three times the strength of its equivalent ceramic or mineral fiber competitors and can operate at a wide range of gas velocity. Typical particulate emission levels are less than 1mg/m3 even when filtering particles less than 1 micron in diameter.

These extremely low levels are unattainable by other technologies.

TENMAT filters are totally incombustible, are highly resistant to thermal shock and can be used in conjunction with a wide range of reagents and sorbents to collect acid gases and dioxins.

Typical applications include atmospheric pollution control (APC) and in line equipment protection (ILEP) operations.

FIREFLY filters in conjunction with proper sorbents can safely remove acid gases, dioxins, furanes and heavy metals at a wide operating temperature range from 50°C to 1,100°C.

This innovative TENMAT solution increases overall plant efficiency, protects downstream equipment and helps reducing emissions.

The current applications are many and varied. They can be listed under the two main headings of Atmospheric Pollution Control (APC) and In Line Equipment Protection (ILEP).

DDDAPC

- Incineration of industrial, chemical and nuclear waste.

- Incineration of clinical, animal and domestic waste.

- Vitrification of incinerated waste.

- Metallurgical processing - ferrous and non-ferrous.

- Precious metal recovery.

- Soil remediation and reclamation.

- Coal derivative manufacture.

- Wood waste burning.

- Glass, brick and cement industries.

DDDILEP

- Gasification and pyrolitic processes.

- Catalyst poisoning reduction.

- Waste to energy plants.

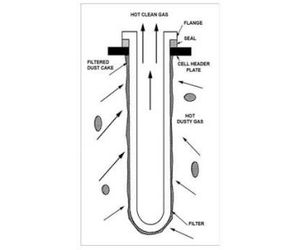

The filter elements are located in the cell plate of the filter house which separates the clean from the dirty side plenum. Dust laden hot gas enters the filter house on the dirty side and is drawn through the filter elements by means of the external fan. The dust particles and sorbents, if used, are collected on the outer surface of the element and the cleaned gas passes through the wall to exit from the mouth of the flange to the clean side. The particulate matter retained upon the filter`s surface assists in the filtration of further dust particles from the hot flue gas. The dust cake is allowed to build up until the filter house pressure drop reaches design level which initiates the cleaning or regenerative cycle.

The accumulated dust cake is removed from the filter element by reverse jet cleaning using compressed gas. A pressure drop sensor or electronic timing device activates a pilot valve which in turn opens a diaphragm valve allowing a short pulse of the compressed gas into the blow tube. The pulse of gas enters the mouth of the filter element via a venturi nozzle, if fitted. The momentary reversal of the gas flow and pressure results in the removal of the required amount of the dust cake from the outer surface of the filter element. The dust cake is released in lumps rather than a fine dust and is a phenomenon identified as `patchy cleaning`. The lumps of dust fall into the hopper section and into a bin or some other removal device. The filter element is then ready for the next dust collection phase.

FIREFLY Hot Gas Filter elements are available in closed end tubes of various sizes.The standard elements have T flanges and are available in two broad size ranges.

The smaller Candle filter elements are 60 mm diameter and are popular for relatively low gas volumes.

The much larger `BIG TUBE` elements are able to filter much greater gas volumes and are able to replace most popular sizes of bag filter.

They are nominally 125 mm and 150 mm external diameter with various lengths.

FIREFLY HGF elements are designed for the filtration of dry particulate from a hot gaseous phase. However, other chemical pollutants are very often present in the exhaust from furnaces and incinerators. These pollutants, such as acid gases and dioxins, can be removed by the use of selective reagents or sorbents.

Acid Gases

Acid gases can be captured by using Sodium Bicarbonate, which has proven to be more efficient than lime at these high temperatures.

The efficiency of neutralization with Sodium Bicarbonate is 99% for Hydrogen Chloride HCI and 95% for Sulphur Dioxide SO2, for flue gases containing a maximum of 1000 mg/m3 with a stoichiometric ratio of 1:5.

Dioxins and Furanes

Low levels may be captured using Sodium Bicarbonate but it is more effective to use Activated Carbon.

Heavy Metals

The common metals e.g. Mercury can be captured by Sodium Bicarbonate and/or mixtures containing carbon.

Other particle agglomeration reagents can be employed if the Particle Size Distribution of the particles in the gas stream is particularly fine e.g. less than 0.1 micron.

These sorbents can be premixed with the dirty gas to facilitate extra reaction time or injected straight into the ductwork leading to the filter house.

Hot Gas Filtration is a technology that possesses distinct advantages over traditional filtration methodologies.

TENMAT filters guarantee cleaner emissions compared to any electrostatic precipitator or wet scrubber, as well as lower capital and operational costs. HGF is the only known technology that will meet the regulations of the future.

Advantages Over Fabric and Low Density Ceramics

High temperature capability

CS1150 Filters can be used in applications up to 1,000°C

Fireproof

FIREFLY filter elements are non-combustible and can withstand even the thermal shock of fires.

Filtration Efficiency

Practical application experience and independent testing have shown FIREFLY HGF elements to be capable of achieving atmospheric emissions of less than 1mg/m3

HEPA rated

Chemical Resistance

CS1150F material is chemically inert to most acid and alkali environments.

Cost effective

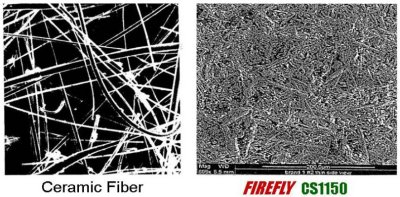

Unique Material Composition results in a unique microstructure