- Home

- Companies

- Williams Patent Crusher & Pulverizer ...

- Products

- Williams - Impact Dryer Mills

Williams - Impact Dryer Mills

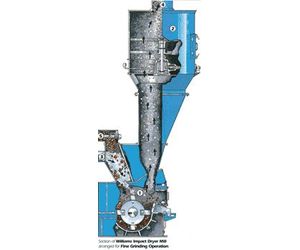

Proven technology integrated into a complete system that simultaneously grinds and dries, accurately classifies, and conveys materials in one continuous, automated operation. Some of the many applications for Williams Impact Dryer Mills include: drying & grinding by-product gypsum from power plant scrubbers for wall board manufacturers; drying & grinding filter cake (as well as other finely divided agglomerates) to a fine, dry powder; reduce clays and other minerals, such as pigments, to extreme fineness; grinding coal to proper fineness for burning in suspension or coal gasification.

Complete automation makes grinding, drying, sizing, and conveying a "push button" operation.

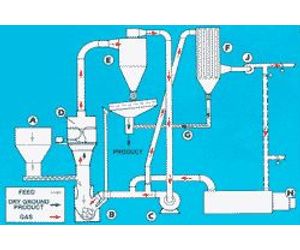

Operation of the Williams Impact Dryer Mill system is completely automated. Feeder (A) introduces raw material into the grinding chamber (B) along with heated gas at a rate that is determined by pressure and temperature sensors located in the system and adjusted automatically. In the grinding chamber, controlled action by the rotating hammers reduces feed to the desired product size. Simultaneously, the hot gas removes moisture. Drying is greatly accelerated by the increased surface area as the particle size is reduced. Controlled velocity in the grinding chamber enables the flow of hot gas to selectively air convey particles, ground to the proper size, up and out of the grinding chamber. Airflow is maintained by the main mill fan (C). The ground product, suspended in air, passes through the adjustable Williams Spinner Separator or Velocity Separator (D) where an accurate size classification is made.

Product-sized material is removed from the air-stream by the cyclone collector (E). Airborne fines which remain entrained in the exhaust gas from the cyclone collector are moved by a high-efficiency fabric dust collector (F). Extreme fines are transported by a second conveyor (G). An exhaust fan discharges clean gases and evaporated moisture from the system.

Patented Inert Gas System: To process explosive material such as coal, and to process all materials with greater thermal efficiency, portions of the exhaust gas generated by exhaust fan (J) can be recycled to burner (H) where the oxygen is consumed in the combustion process.

- Fluid bed drying and grinding chamber: Controlled velocity in the grinding chamber combined with increased product surface area, resulting from size reduction, accelerates fluidized bed drying.

- Adjustable Spinner Separator: Micrometer control of finished product size is possible with Williams Spinner Separator which controls product size accurately, yet permits in-process adjustment of product by means of externally mounted variable speed drive.

- High Capacity air conveying: Gases used for drying convey the finished product from the grinding chamber to final storage. Elimination of mechanical conveying equipment thereby reduces material handling costs.

- Completely enclosed system: Dustless operation of pneumatic material handling assures cleanliness and reduces house-keeping expenses. A slight negative pressure is maintained to prevent leaks from the system.

- Automatic variable-speed feeder: Live-bottom bin feeders for wet, sticky materials, or rotary pocket feeders for granular materials such as coal, are controlled by conditions in the grinding chamber to provide proper feed rate automatically. The basic Williams rotary pocket feeder, variable rate vibratory feeder, or multiple screw feeder are all available to help Williams match the feeder to the job for optimum performance in your operation.

- Drive Motors (not shown): Drive motors for the main mill fan, feeder, and separator are standard, readily available TEFC motors.