- Home

- Companies

- InduMar Products, Inc.

- Products

- InduMar - Model SaddleWrap - In-Field ...

InduMar - Model SaddleWrap -In-Field Composite Wrap System

The SaddleWrap" system is a fast curing, in-field composite wrap system, ideal for joint reinforcement and abrasion resistance in saddle support applications.

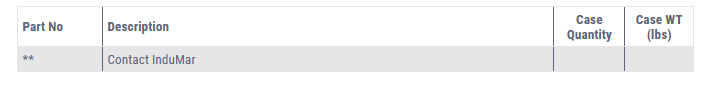

The SaddleWrap" system includes a strong fiberglass knitted tape, precoated with fast setting water-activated urethane resins, installation simply involves wrapping the tape around the area in need of protection. SaddleWrap" can be installed by one person with no special tools or hot work, and provides for quick, in-field applications, regardless of weather conditions, pipe orientation, or local geometries. Recommended for use on pipes less than 12 inches in diameter. We recommend contacting InduMar with the specific conditions and requirements of your project.

- Can be applied to wet or dry surfaces

- Superior resistance to environmental degradation

- Excellent abrasion and impact resistance

- Strong adhesion to pipe surfaces

- Water-activated urethane resin system cures to form an inert, fully encasing matrix

- Requires minimal pipe preparation

- Knitted fiberglass construction ensures excellent conformability to tees, elbows, saddles, joints, and step profiles

Each SaddleWrap" kit contains a 4"x25` roll of knitted fiberglass tape ptecoated with water-activated polyurethane resin enclosed in a sealed foil pouch, latex gloves and printed SaddleWrap`" instructions.

- Set Time: Tack free in 3 to 5 minutes at ambient temperatures of 50°F to 8CTF (1CTC to 27BC). Set time is slower below 50BF and faster above 80aF

- Heat Resistance: From -20BF up to 250*F (-29eC to 121 °C) - continuous. From 250eF to 500eF (121BC to 260eC) - temporary exposures

- Shelf Life: 2 years from date of purchase when stored at 40aF to 83°F (5°C to 28SC) with proper stock rotation

- Color: Black

- Tensile Strength: 24.950 PSI/in width /172 MPa (ASTM D 3039).

- Modulus: 62.505 PSI/4309 MPa (ASTM D 3039).

- Flexural Yield Strength: 12.005 PSI / 82.77 MPa (ASTM 790).

- Durometer Hardness: 63 Shore D (ASTM D 2240) measured at full cure.