InduMar - Model XCorr HP 100 & 200 -Leak Sealing Products

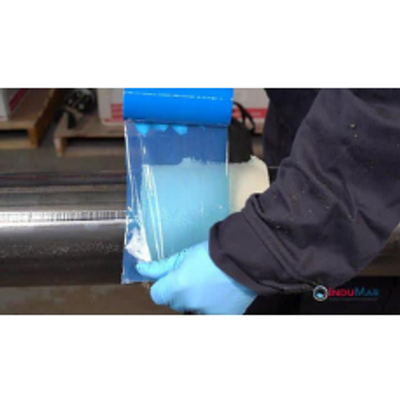

XCorr HP is a multi-component epoxy composite repair system designed for high-pressure sealing applications. The repair system provides a built in 4:1 safety margin. XCorr® HP utilizes a premeasured 2-part epoxy system combined with high performance fiberglass reinforcement fabrics and a technical felt to provide superior leak sealing capacity with strong interfacial bonding.

The product line is differentiated by operating temperature with XCorr® HP 100 rated for temperatures up to 350BF (177°C) and XCorr® HP 200 rated to 450eF (232aC).

XCorr® HP 100 is recommended for high pressure applications up to 1.500 psi (105 kg/cm2) with a built in 4:1 safety margin. Return to service in high pressure process piping may be accomplished in -5 hours.

XCorr® HP 200 is recommended for high pressure applications up to 2.060 psi (144 kg/cm2) with a built in 4:1 safety margin. Return to service in high pressure process piping may be accomplished in -10 hours.

See below for more information on physical properties for the resin and composite materials.

- Novolac epoxy resin yields exceptional chemical resistance

- 100% solids. No VOCs

- 3:1 mixing ratio (pre-measured)

- Cartridge dispensing minimizes waste, ensures complete mixing, and manages pot life

- Fiberglass weave provides multidirectional mechanical reinforcement and conformability to irregular geometries

- Primary technical felt layer ensures complete interfacial wetting and highest pressure performance

- Outstanding compressive and adhesive bond strength

- Produces durable coating that will not shatter under extreme operating conditions

- Accelerated cure times are possible with annealing of the installed repair

XCorr® HP 100 Properties

Resin at 75°F (24°C)*

- Pot Life: 35 minutes

- Dry To Toach: 4 hours

- Full Mechanical SbengUi: 24 hours

- Full Chemical Resistance: 24 hours

Composite

- Layer Thickness (per ply): 0.015 in

- Lap Shear Adhesion: 1,320 psi (ASTM D 3165)

- Dry Adhesion: -3,000 psi (ASTM 4541)

- Wet Adhesion: -3,000 psi, 5 days 158*F (70`C) water (ASTM 4541)

- Sealing Pressure: 1,500 psi, 1/8` od hole in 1* steel pipe, 4:1 safety (actor

- Compressive Strength: 10,000 psi (ASTM C109)

- Shore D Hardness: 84 (ASTM D 785)

- Temperature/Heat Resistance: From -20*F up to 350°F (-29`C to 177°C) -continuous, dry. Consult chemical compatibility to gauge net service performance.

XCorr® HP 200 Properties

Resin at 75°F (24°C)*

- Pot Lrte: 35 minutes

- Dry To Touch: 6 hours

- Full Mechanical Strength: 24 hours

- Full Chemical Resistance: 24 hours

Composite

- Layer Thickness (per ply): 0.015 in

- Lap Shear Adhesion: 1,480 psi (ASTM D 3165)

- Dry Adhesion: >2500 psi (ASTM 4541)

- Wet Adhesion: >2500 psi, 5 days 158*F (70*C) water(ASTM4541)

- Sealing Pressure: 2060 psi, 1/8` od hole in 1* steel pipe, 4:1 safety (actor

- Compressive Strength: 10,000 psi (ASTM C109)

- Shore 0 Hardness: 84 (ASTM 0 785)

- Temperature/Heat Resistance: From -20*F up to 450°F (-29`C to 232°C) -continuous, dry. Consult chemical compatibility to gauge wet service performance.

* Pot life is greatly reduced with increased mixing volume end temperature. Cure time is significantly extended at lower temperature.

- Packaging: Resin supplied in dual cartridge (pans A and B packaged separately) with pre-measured volumes sized specifically for full coverage of supplied reinforcement fabric. Kits provided with static mixers, spreaders and gloves. Two-part dispensing guns sold separately.

- Sizes: Reinforcement tape supplied in 6* widths and premeasured lengths. The required resin volumes are supplied in ready to use 400 mL or 1.0 L dual cartridge assemblies.

- Shelf Life: Part A; 12 months at 75`F (24T). Part B: 12 months at 75`F (24eC)

- Storage Temperature: 32 to 100°F (0 to 43`C), 0-100% relative humidity

- Application Temperature: 50 to 150eF (10 to 65eC)

- Surface Preparation: Surfaces must be cleaned of all oil and debris and dried. For metal surface, a bright metal finish is desired (SSPC-SP10 (immersion) or SSPC-SP6 (non-immersion)). If possible, the pipe should be at ambient temperature before application.

- 07