- Home

- Companies

- Control Instruments Corporation (CIC)

- Products

- AcuPro - Infrared Process Analyzer

AcuPro - Infrared Process Analyzer

The AcuPro is an industrial strength analyzer for continuous measurement of flammable and some combustible vapors, from 0% to 100% of the Lower Flammable Limit (LFL/LEL).

- Accurate: Multiple Wavelengths detect broad range of solvents & gases without recalibration

- Reliable: Response factors with minimum variation

- Fast: Superior response time, less than 4 Seconds

- No Add-ons: Accessories, moving parts, or mirrors are not necessary

- Fully Heated: All sample-wetted parts are heated, including the detector assembly, the optical cell, & sample probe

- Industrial Design: Immune to poisoning and requires no oxygen for operation

The AcuPro Infrared Analyzer from Control Instruments Corporation is an industrial strength analyzer with a complete sampling system, heated optical cell, and integrated controller for continuous measurement of flammable and some combustible vapors. It can accurately monitor a given range of solvents within a narrow band to optimize both the safety and the economy of running a process; it can also be used for mixtures of solvents in processes where normal solvent concentrations are below 25% LFL.

This analyzer was built on a robust and well-proven industrial analyzer platform. Its unique sample delivery system is heated, mirrorless, and free of moving parts which means it is specifically designed to handle a wide variety of process monitoring environments. In addition, the multiple wavelength infrared detector allows the AcuPro to operate with linearity and with common response factors while minimizing the need to continually recalibrate for different solvents. All this is accomplished without compromising safety, and in accordance with NFPA guidelines, not to mention with low maintenance and minimal downtime.

Built For Your Process

Unlike other IR point detectors the AcuPro was specifically designed for the process environment. Its sample delivery system is heated to 60°C and uses compressed air to draw in the sample with an aspirator, which provides a controlled sample for accurate readings. This method is simple; it is a complete detection system with no need for add-ons or accessories and to top it off, contains no moving parts, so it requires little maintenance. It is also immune to poisoning and requires no oxygen for operation.

Low Maintenance Features Enhance Accuracy

The AcuPro not only withstands the rigors of the industrial process environment, but performs accurately under them as well. Its mirrorless design reduces the effects of contamination on the optical cell and eliminates surfaces that fog, become dirty, and need to focus. All sample-wetted parts are heated, including the detector assembly, the optical cell, and sample probe, which prevent errors from process temperature changes and condensation of water vapor. In addition, the air aspirated sample draw system eliminates the need for failure-prone pumps. All of these features create an environment where accurate readings can be obtained and ultimately reduce maintenance and downtime.

The AcuPro has a fast response time; the entire system is less than four seconds, due to its advanced signal processing and proprietary detector technology. The assembly mounts directly onto the process ductwork, as close as possible to the sample pickup point, which allows the aspirator to draw the sample directly into the cell, accelerating response time.

Different chemical families absorb infrared energy at different wavelengths. The AcuPros multi-wavelength detector enables it to detect more gases, including solvents like Alcohols, Acetates, Ketones and Aromatics. This unique design clement also provides more precise readings, as they cover more of the infrared spectrum and detect the most suitable wavelength for each gas or solvent.

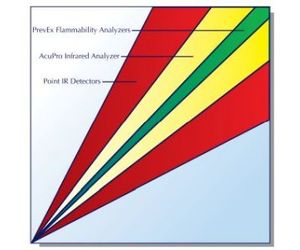

A typical infrared sensor with just one active wavelength has large errors in its response to different gases. Using multiple wavelengths, the AcuPro is like several sensors in one working together to reduce these errors as much as possible, while providing more complete and balanced readings. There is also less chance of false alarms, `The graph to the left illustrates the response to a dozen common solvents, the AcuPro measures these with less variation than any other technology except the industry benchmark, the PrevEx Flammability Analyzer.

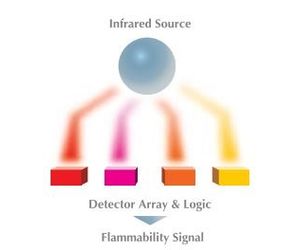

The Technology - How OUR Infrared Analyzer Works

An integrated sampling system extracts a sample from the process using a built-in aspirator that develops suction from compressed air. Infrared energy is passed through the sample, and the amount of infrared energy that is absorbed determines the concentration of solvent vapors. Multiple infrared detectors at select wavelengths help convert concentration data into % LPL flammability readings with greater accuracy for a wider range of solvent types.

The AcuPro incorporates 6 built-in relays to ensure that corrective action is initiated directly by the analyzer, enabling failsafe conditions. These system relays include warning, danger, fault, horn, calibration-in-progress and service needed. Other standard outputs include a 4-20mA analog output and an RS-485 serial port with Modbus protocol for digital access to all readings and settings.

The AcuPro is excellent for flammable gas monitoring in relatively clean, low temperature, low concentration applications. Its suitable for single or select solvent ranges. These applications include, Flexographic & Rotogravure Printing, Pharmaceutical, Coating, Painting, Aerosol Filling, and many others! If your process uses higher temperatures and concentrations or if your solvent mixture might change in the future, we offer the proven PrevEx Flammability Analyzers.

When selecting an analyzer, its always a good idea to enlist the advice of a specialist in the field. Do not assume that "one size fits all" or that the analyzer which was correct for a previous job will also be the right choice for another application. Whether new or similar, the specific details of each application need to be examined closely to prevent disaster. The application survey that a manufacturers technical sales representative or engineer asks you to fill out is a critical part of this selection process.

Choosing the right kind of instrument can be a detailed task, even for those familiar with the process. The instrument of choice may vary from one application to the next, but the correct process analyzer will always be fast, accurate, and fail-safe. In most cases, it will also be able to read a wide range of flammable substances.

Find Out More Today

Control Instruments Corporation has been engineering solutions to gas and solvent vapor monitoring problems since 1969. We work hard to assess your risks and carefully tailor a monitoring system to meet your needs.