- Home

- Companies

- KRACHT GmbH

- Products

- KRACHT - KM 1

KRACHT - KM 1

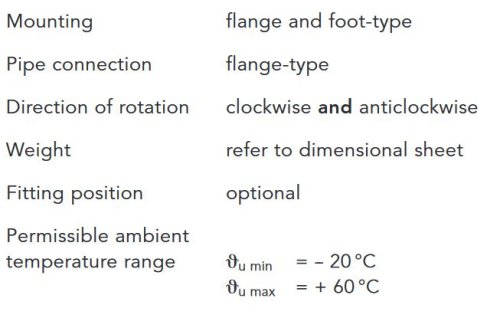

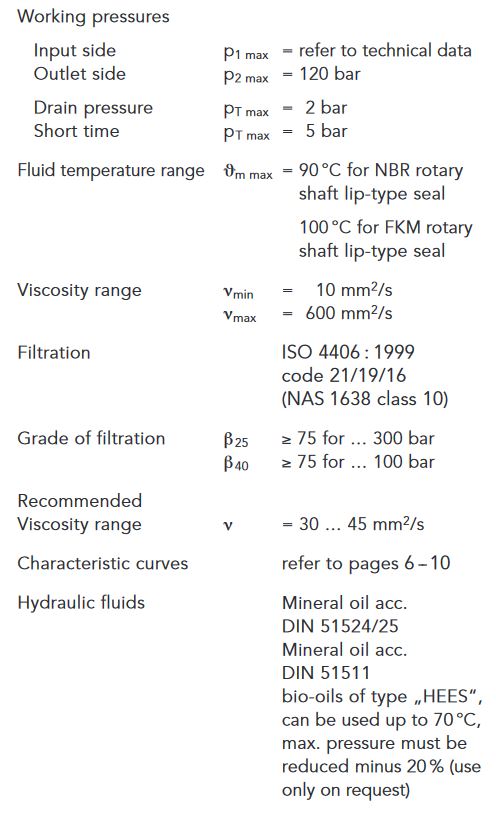

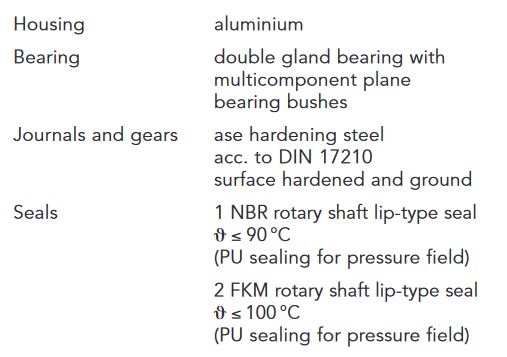

Accordingly to its configuration - the Design principle is illustrated by the Sectional figure above - the KRACHT External Gear-Type Motor Series KM 1 is classified in the category of the so-called Gland-Type Bearing Motors.All essential functional parts as the gearing and the gland bearings are located in an aluminium housing manufactured of a high strength extrusion alloy which is closed on each side by an end cover or by a flange mounting cover respectively.

The gearing of case hardening steel in surface hardened condition consists of the pinion shaft and the pinion.

Highest manufacturing quality is assured by grinding and honing of the tooth flanks.

The surfaces of the journals are super finished.

An important reduction of the type dependent deviation of the volumetric flow and of the pressure pulsation was achieved on the basis of the great teeth number (z - 13) and the specially shaped teeth.

The gland bearings located on both sides of the gearing carry the journals in heavy duty multicomponent plane bearing bushes and contain additionally those sealing elements which serve for the pressure field sealing to compensate the axial clearance.

If requested the engines with built up special valve can be delivered. Multiple engine combinations are possible.

The optimal design of the pressure fields guarantees very good efficiencies over a wide pressure/speed range on the one hand - at the nominal working point for instance a total efficiency of 90% and above is reached -and ensures a smooth starting behaviour of the motor on the other hand and that already at a low rate of the input flow.

As the pressure fields are symmetrically arranged the motors can be used as well for clockwise as for anticlockwise rotation (reversible working modes).

The pressure relief of the shaft seal is effected by the drain port to be found in the end cover, (note the max. permissible drain pressure) so that the motors may be pressurized at the outlet side, hence follows that it is possible to connect together several motors in series.

For high speed Operation the shaft seal must be of FKM-material, refer to page 5. The combination of 2 motors for instance coupled together and provided with a common supply line makes a Flow Divider with a high dividing accuracy.

Displacement: 1.5 ... 25 cm³/r

Working pressure: ... 280 bar

Viscosity: 10 ... 800 mm²/s

Media temperature: −20 … 150 °C