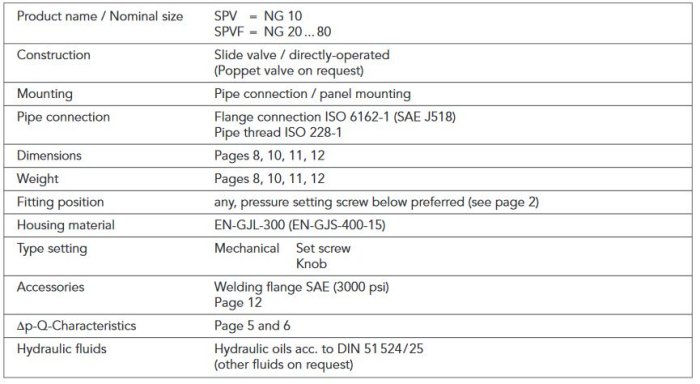

KRACHT - SPV / SPVF

Notes-

- When using strongly aerated media, the valve shouldpreferably be mounted vertical with the setscrew facing down.

- The tank connection Tof the valve must not be exposed to underpressure when subject to flow (Q > 0), as in this case the valve cannot be ventilated, possibly resulting in unwanted vibrations and noise. If this is unavoidable, the special solution (S33) provides an alternative

The sliding piston 2 is pressed against the annulated area a by the compression spring 3. Thus the pressure connection P is separated from the tank connection T by sealing the diameter d. As soon as the opening pressure p is achieved, adjusted by the set screw 4, the sliding piston 2 releases the fluid flow to the tank connection. The spring chamber b is pressure compensated by the bore c. When starting-up the valve the spring chamber b must be blee-ded by the bleeding screw 5, (hex. socket width: 4). The pressure relief valves are available in different pressure setting ranges because, due to their springrates, each of the compression springs can only cover a limited pressure sotting range.

Explosion protection - Field of application for the pressure relief valves.

The valve is used to secure low pressure hydraulic circuits with various flammable and non-flammable fluids.

They can be used:

- In Zone 2 {Gas-Ex, Category 3G) in the explosion groups IIA, IIB and IIC

- In Zone 22 (Dust-Ex, Category 3D), in the explosion groups III A and III B at non-conductive dusts with a minimum ignition energy >1mJ

- In Zone 1 (Gas-Ex, Category 2G) in explosion groups IIA, IIB and IIC

- In Zone 21 (Dust-Ex, Category 2D) in the explosion groups III A and III B at non-conductive dusts with a minimum ignition energy >1mJ

The qualification for the surface temperature is T4; for all gases, vapours, mists with an ignition temperature >135°C, the operating materials are not an ignition source.

In the Dust-Ex area, 135°C is the reference temperature for further considerations regarding the safety margin to the glow temperature, etc. {can only be decided by the operating company).

The permissible ambient temperature ranges from

- -20°C*Ta£60°C-NBR,CR

- -15°CsTas60°C-FKM, HNBR

- Flashpoint, minimum ignition temperature and media-specific attributes must be complied with by the operating organisation.

- No not allow any explosive mixture to be present inside the unit.

Marking according to the Machine Directive 2014/34/EU

- Manufacturer : KRACHTGmbH D-58791 Werdohl

- Type designation Consignment no., SPV...

- Year of manufacture : xxxxxx/xx-xxx xx.xx

- Tech. File Ref.: TRR: 04.02X

- Protection type marking : ©N2GDEExcllC(T4) or ©H2GDEExc(T4)

Nominal size: 10 - 20/25 - 32/40 - 50 - 80

max. flow rate: ... 800 l/min

Nominal pressure: max. 120 bar

Viscosity: 1.2 ... 1000 mm³/s

Media temperature: -20 ... 350 °C