Primary Flow Signal, Inc. (PFS)

- Home

- Companies

- Primary Flow Signal, Inc. (PFS)

- Products

- PFS - Model ASME - Long Radius Flow ...

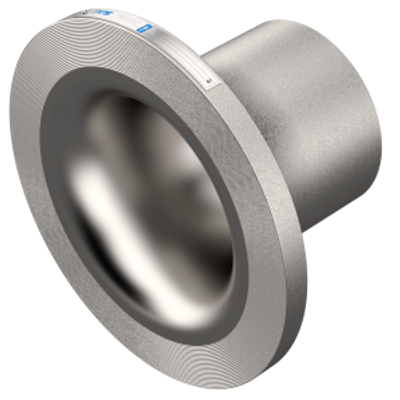

PFS - Model ASME -Long Radius Flow Nozzle Meter

The Long Radius Flow Nozzle is generally used for the measurement of liquid or gas flows including steam, non-viscous, erosive and high-velocity media. It does not rely on a sharp edge (which can deteriorate over time) to maintain accuracy and therefore offers excellent long-term accuracy with less wear, reducing the possibility of measurement error over time.

Most popular related searches

process water treatment

flow meter

restriction orifice union

pipe lining

process water

water treatment

process water treatment system

water process treatment

water treatment system

process gas treatment

+/- 2.00% Uncalibrated Uncertainty

Liquids and Gases, High-Velocity Flow

- Line size: 2 to 24 inches

- Head loss % of Differential: 30 to 85 percent, Beta Dependent

- Recommended Pipe Reynolds number: Greater than 10,000 for basic accuracy

Flow nozzles are capable of measuring higher flow rates, often double, than an equivalent orifice plate at the same differential pressure. The flow nozzle is available in various designs including mechanically clamped between flanges or permanently welded directly into the pipe line.

- Line Size: 2 to 24 inches

- Headloss % of Differential: 30 to 85 percent, Beta Dependent

- Basic Accuracy (% of Total): (Calibrated) +/- 0.25 (Uncalibrated) +/- 1.00 to +/-2.00 (PTC19.5, MFC3M)

- Minimum Pipe Reynolds Number: Greater than 10,000

- Required Straight Piping: Consult PFS for required US & DS piping based on your specific application

- Beta Range: 0.20 through 0.80

- Useful Service Life: Medium to Long

- Service Functional Limits: Clear Liquids, Gas and Steam

- Applications: Power Generation, Hydrocarbon, Liquids, Gas Process, Water Treatment distribution, Oil production and refining, Steam Process, High Velocity Process, Erosive Fluids

- Common Materials: Carbon Steel, Stainless Steel, Chrome Moly

- Other Available Materials not limited to: Aluminum, Zirconium, Hastelloy, Monel, Duplex SS, Titanium, Tantalum, 321SS