- Home

- Companies

- Guangzhou Shincci Energy Equipment Co., ...

- Products

- Shincci - Low Temperature ...

Shincci - Low Temperature Multiple-Effect Concentrators

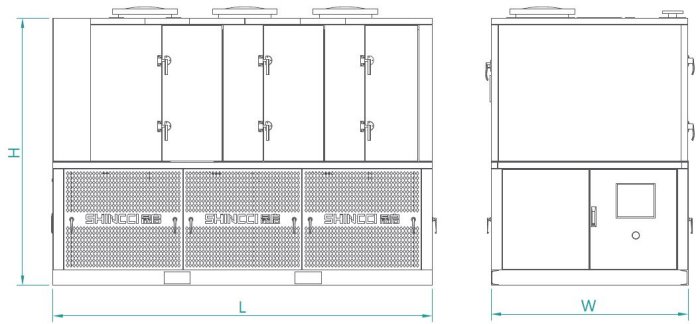

Technical Features: With easy-to-open access door and the easy-to-remove heat exchanger cover make machine maintenance and cleaning easier. Heat exchanger is designed with high flow rate forced circulation to reduce the scaling maintenance. Adopt four-effect evaporation and concentration design , which saves 75% energy comparing to one-effect evaporation. Evaporation and concentration under low temperature and vacuum can realize continuous feeding and continuous discharging. Multi-stage low-temperature evaporation concentration can effectively control discharge concentration, and live concentration monitoring control can realize automatic discharge. Realize low temperature evaporation in range of 20~60 degrees (one-effect to four- effect) and effectively maintain product ingredients. Patented integrated design structure, compact equipment and small footprint. Full-automatic intelligent PLC touch screen control.

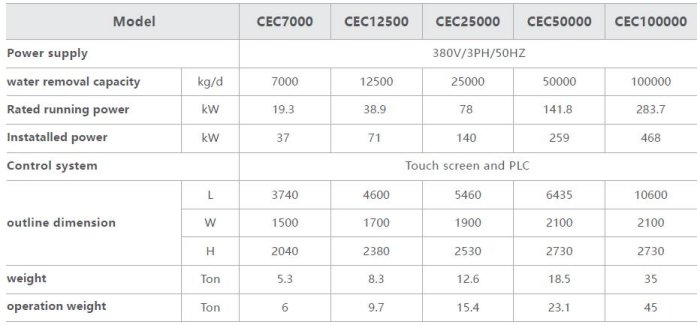

Heat Pump Type

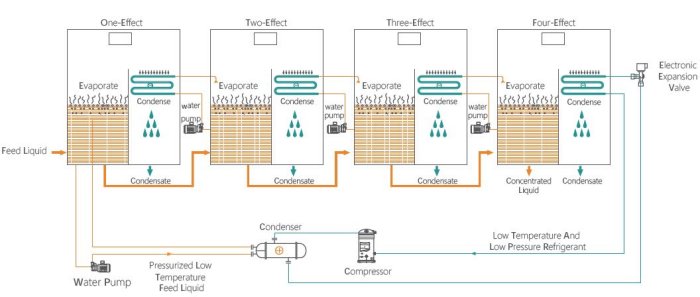

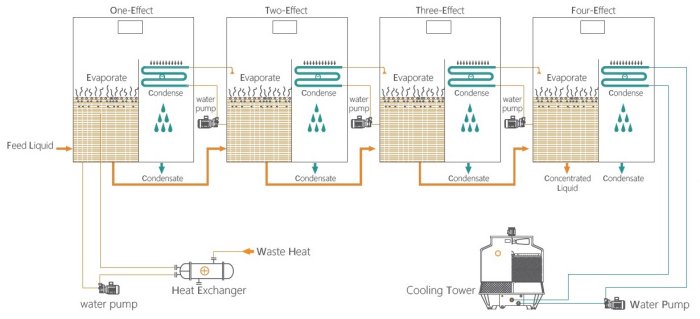

- The one-effect feed liquid is heated by condensation heat under vacuum and then boils and evaporates, and the low temperature vapor is cooled into condensate water by the two- effect condenser and discharged outside the machine

- After being thickened by the one-effect evaporation, the feed liquid enters the two-effect evaporation chamber. Feed liquid is heated by the two-effect heater and then boils and evaporates. The low temperature vapor is cooled into condensate by the three-effect condenser and discharged outside the machine

- The feed liquid enters the three-effect evaporation chamber after being concentrated by the two-effect evaporation. The three-effect feed liquid is heated by the three-effect heater and then boils and evaporates. The low-temperature vapor is cooled into condensate by the four-effect condenser and discharged outside the machine;

- After thickened by three-effect evaporation, the feed liquid enters the four-effect evaporation chamber. The four-effect feed liquid is heated by the four-effect heater and then boils and evaporates. The low-temperature vapor is cooled into condensate by the heat pump evaporator and discharged outside the machine;

- The latent heat of the refrigerant recovered by the four-effect heat pump evaporator works through the compressor and heats the one-effect feed liquid through the heat pump condenser; The feed liquid passes through one-effect, two-effect and three-effect discharged from the machine after multi-effect concentration.

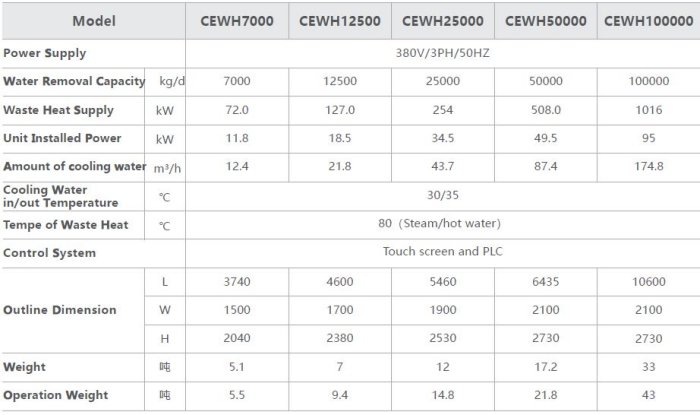

- The one-effect feed liquid is heated by the heat source in vacuum and then boils and evaporates, and the low-temperature steam is cooled into condensate by the two-effect condenser and discharged outside the machine

- After being concentrated by the one-effect evaporation, the feed liquid enters the two-effect evaporation chamber. The two-effect feed liquid is heated by the two-effect heater and then boils and evaporates. The low temperature steam is cooled into condensate by the three- effect condenser and discharged outside the machine

- The feed liquid enters the three-effect evaporation chamber after being concentrated by the two-effect evaporation. The three-effect feed liquid is heated by the three-effect heater and then boils and evaporates. The low-temperature steam is cooled into condensate by the four-effect condenser and discharged outside the machine

- After concentration by three-effect evaporation, the feed liquid enters the four-effect evaporation chamber. The four-effect feed liquid is heated by the four-effect heater and then boils and evaporates. The low temperature steam is cooled into condensate water by the cooler and discharged outside the machine

- The cooling heat is discharged from the engine through the cooling system

- The feed liquid passes through one- effect, two- effect and three-effect. After multi-effect concentration, it is discharged outside the machine.

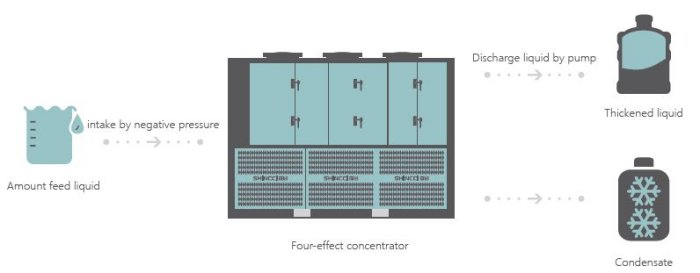

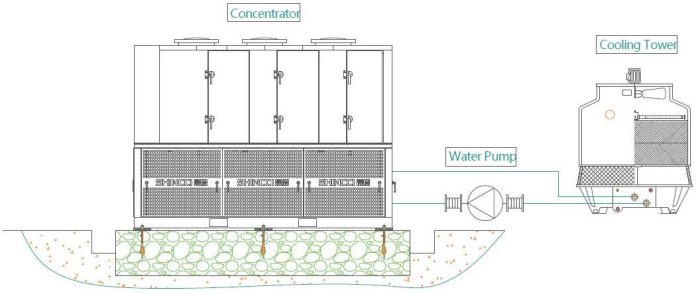

A large amount of feed liquid is intake by the concentrator machine under negative pressure, and a small amount of thickened liquid is discharged by pump after treatment; condensed water is forced out by the water pump.