- Home

- Companies

- Hasler Group

- Products

- Mammuthus Clinker - Apron Extractor ...

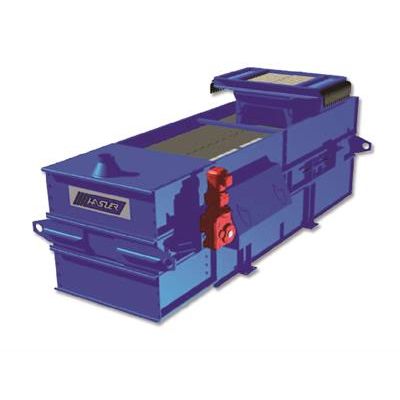

Mammuthus Clinker - Apron Extractor Weigh Feeder

The MAMMUTHUS CLINKER is a device used both as a strong apron feeder and as a common weigh belt feeder. The speed is controlled according to the material load in order to obtain a constant and accurate flowrate. The load is measured by two digital load cells (integrated weighbridge) through the rails deflection. An index flow sensor (one per lap) synchronises the segmented detaring of the empty apron. A pulse generator integrated to the gear motor gives the speed of the conveyor. The MAMMUTHUS CLINKER can extract hot and abrasive products such as clinker in different industrial applications.

- Weighing

- Flow rate calculation

- Totalization

- Every kind of activity / conveyed materials

- Accuracy ± 1%

- Modular apron width

- Long lasting reference in our range of products

- Constant technical evolution

- Available in 4 widths as a standard

- Easy maintenance

- Entirely closed (Option)

- Double chain traction

- Embedded digital weigh system

- Speed control system of the feeding movement

- Inspection doors to ease maintenance

Spillage Conveyor :

One or more cross scraper(s) driven by two side chains recover the particles that escaped from the weighfeeder and bring back to the common discharge.

Other options :

Rod closing gates

The SCM2 controller directly receives the signals and informations from the sensors: weight, speed and Index. It can calculate the flowrate, totalization and speed control signal.

Informations and alarms are deported on the SDU display

* SCM2 Field or Panel Version : See SCM2-F.260.001-E or SCM2-P.260.001-E