- Home

- Companies

- Process Engineering Srl

- Products

- Helier - Model hC - Mass Transfer ...

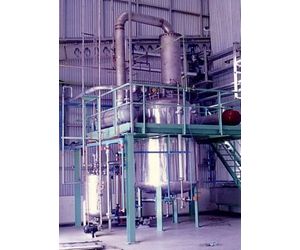

Helier - Model hC -Mass Transfer Operations

Columns and Plants for Mass Transfer Operation such as Absorption, Desorption, Stripping and Similar. The use of the helier-Structured Packing - hSP - permits the realization of Structured Columns for Mass Transfer. characterized by:High Transfer Efficiency. Low Pressure Drops. Reduced Fouling. Reduced Column Dimension. The lowest Column Operating Cost.

The helier Columns - hSP – are be successfully applied in the process plants for Mass Transfer Operations, such as:

- Liquid / Liquid Operation

- Gas / Liquid Operation

- NOx Absorption

- Stripping

- Washing

- Distillation

- Distillation with Solvent

The helier Book describes the complete path that has led to the characterization of the Main Properties of Structured Columns with helier to be applied in the Mass Transfer Operations.

In particular, the helier Book reports the information and the results obtained

- during the Experimental Activity conducted at the University of Pisa to characterize the base properties of the helier packing;

- from the Experimental Test executed at the University of Pisa to determine the Properties and the Operation of Industrial Structured Columns with helier;

- the Model of Calculation / Simulation developed in collaboration with the team of Prof Nardini and Prof Paglianti;

- the Scientific Articles published in scientific journals by the team of Prof Paglianti and Prof Nardini, as a result of their research activities in Mass Transfer Operations.

The helier Columns are complete Package that optimize the use of the helier-Structured Packing - hSP - in the Mass Transfer Operation for which they are chosen.

The Package include:

- the optimization of the mass transfer process

- the supply of the proper column/columns fot the application

- the Plant Utilities pumps,ricicling pumps, compressor, blowers … … whatever needed to the operation

- the supply of regulation (valves, flow meters ...)

- the Process Utilities if required (compred air, vapour … heat exchangers )

- the supply of controls (Temperature, Pressure ... PLC)

- the Power Panels for the Plant Utilities

- the Control Panel to control and regulate the Column / Package

- the PLC & Software Systemto Control, Regulate, Manage and Synchronize with the Data Storage System of the operation parameters

for the good operation of the system.

The helier Columns - hSP – have

- High Efficiency

- the Lowest Operating Cost

- the Lowest Production Cost per Transfer Unit.

These properties have been duly documented by the Industrial Research done by the University of Pisa and by the consequent scientific bibliography than edited, such as :

A) “ An Economic Analysis on Packed Columns for Absorption ”

B) “ Performance of Absorption Columns Equipped with Low Pressure Drops Structured Packing ”

C) “ Absorption of Nitrogen Oxides in Columns Equipped with Low Pressure Drop Structured Packing ”

D) “ Studio Teorico Sperimentale sui Riempimenti Tipo Jet-Helix ”

The above Scientific Articles have been published in magazines and major institutions such as:

A) La Chimica e L’Industria

B) Industrial Engineering & Chemical Research

C) Chem. Biochem. Eng

D) Dipartimento di Ingegneria Chimica – Università di Pisa.

All the results of the Industrial Experimentation and Testing done by the University of Pisa by the team of Prof Nardini and Prof Paglianti is completely reported in the helier Book.

Between the various Industrial Application where the helier Columns - HC - can be successfully applied, we indicate:

Stripping Operation

- Ammonia (NH3)

- Carbon Dioxide(CO2)

- Hydrogen Sulphite (H2S)

- Organic Solvents(BTEX, MTBE ... )

Absorption Operations

- Acid Substances and Pollutants

- Basic Substances and Pollutants

- Organic Substances

- Obnoxious Substances

- Water Soluble Substances

- Separation

- Up-grading e Revamping of existing Plants

For the recovery, the Purification and the Distillation of Acetic Acid from Waste Waters with a Dilute Solution of Acetic Acid.

The use of the ‘helier-Structured Packing’ permitted to upgrade the Purification Process, without applying costly and complicated plants solutions.

The efficiency has been increased so far so that a recovery higher than 80% of the Acetic Acid available in the waste water coming from the production process before the AA Purification Plant has been obtained.

The recovered Acetic Acid is reutilized again in the production process before the AA Purification unit, so providing the

- abatement of the production cost

- reduction of environmental pollution

Design of the helier Columns

Each helier Columns must be designed in function of

- the application

- the working conditions

- the Client specifications

- using the proper helier simulation software ( “helier – Adsorption 3.0”, “helier – desorption 2,5”) purposely developed in cooperation with the University of Pisa .

The helier simulation softwares apply a model that interpolates the results of the Industrial Experimentation and Testing done on this Technology.

The helier Columns can have an internal diameter between 0,2 m and 2,2 m .

With regard to the manufacturing materials, the columns can be made using various types of steel although our preference goes to stainless steel AISI.

With regard to the structured packing, the hSP internals can be made with different plastic materials, which are chosen depending on the application.

However, we prefer to use the PPS.

These choices permit us to cover a wide range of application in terms of

- Temperature resistance

- Corrosion resistance

- Pressure resistance