SALHER - Model CHC-OXI-MBR -Membrane bioreactor (MBR)

The CHC-OXI-MBR achieves high yields in the removal of organic matter, suspended solids and ammonium (BOD5: 99%, COD: 95%, N-NH4 +: 82%, SST: 99%, fecal coliforms: 99.9%). It is composed of Salher equipment manufactured in GFRP certified by an external body, with strict quality controls in its production process, which are also compact, modular, highly efficiency and easy to install and commission.

The advantages of these treatment plants compared to others equipment, Salher brand, are:

- Exceptional quality of the effluent. Water quality for water reuse, according to regulation RD1620 / 2007. Effluent 100% free of viruses, bacteria and other pathogens.

- Reduction of the necessary area compared to traditional technologies: 65 – 75%. Elimination of the secondary settling tank and reduction of the volume of the biological reactor.

- Substitution of the secondary decanter by ultrafiltration membranes. Technology with perfect separation of clarified water and sludge (liquid fraction of mixed liquor). Elimination of problems associated with the settling of sludge.

- Greater flexibility to face peak flows and contaminating loads.

- Absence of odors. No bulking problems.

- Lower production and greater stabilization of sludge. Increase of sludge ages and decrease of mass loads.

- High degree of automation.

- Possibility of direct reuse for irrigation and other applications.

The elements included in the bio membrane treatment plant CHC-OXI-MBR are:

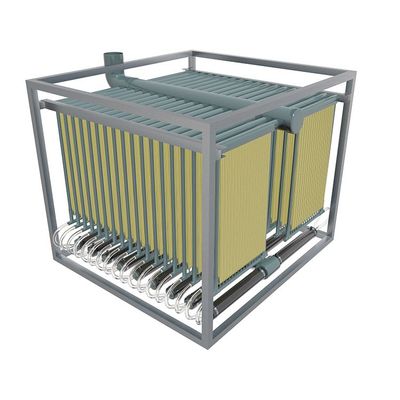

- The MBR, consisting of a set of rack-mounted ultrafiltration modules with diffusers grid and permeate outlet manifold and with two (1 + 1) permeate suction pumps. In addition, it includes a membrane cleaning system.

- The biological reactor, is a vertical GFRP tank that consists of 2 (1 + 1) compressors / rotary piston blower with sou ndproofing cabin, a diffusers grid, a feed pump to the MBR for recirculation and a pump sludge extraction.

- Electrical panel board + automaton.

- Supervision of the installation and commissioning in national territory.

- Documentation: plans, manuals and certificates.

The treatment can also be provided by means of membrane bioreactors (MBR), in civil works, with separate equipment and projects. We refer to our OXI-MBR reference, which has exactly the same advantages and features as the compact wastewater treatment option, but also includes the design and project of the necessary civil works, technical advice on site, with optional work management and the commissioning to adjust the Salher equipment.