Metrosemi - Model 3900 Series -Wafer Defect Inspection and Review Systems

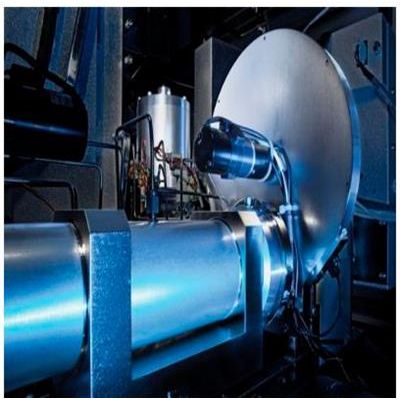

In advance of SEMICON West, KLA-Tencor Corporation (NASDAQ: KLAC) was introduced advanced wafer defect inspection and review systems for leading-edge IC device manufacturing: the 3900 Series (previously referred to as Gen 5) . This system employ a range of innovative technologies to form a comprehensive wafer inspection solution that enables discovery and control of yield-critical defects at all stages of IC manufacturing— from early process characterization to production process monitoring.

The 3900 Series broadband plasma defect inspection systems support wafer-level defect discovery, process debug and excursion monitoring for leading-edge IC devices. The 3900 Series uses innovative hardware technology to produce super resolution deep ultraviolet (SR-DUV) wavelength bands. When used in conjunction with advanced algorithms, such as pin•point™ and super•cell™, the 3900 Series’ SR-DUV provides high sensitivity capture of defects in yield-critical pattern locations on ≤10nm design node devices.

Defect Discovery Process

The 3900 series design and review information to form a defect discovery solution that drives process and yield improvements through the detection and characterization of critical defects. This solution helps IC manufacturers address advanced design node challenges such as process window discovery and yield loss associated with the proliferation of pattern and process systematic defects. The revolutionary 3900 Series broadband plasma optical inspectors utilize a new super resolution deep ultra violet (SR-DUV) wavelength range and scanner-grade stage accuracy to produce superior optical resolution for proven detection of sub-10nm defects. With DUV/UV wavelength bands, the 3900 Series ensures optimal contrast for yield-relevant defect detection across all process layers. Both broadband plasma optical inspectors provide full wafer inspection in approximately an hour, allowing collection of wafer-level and lot-level defect data for a complete understanding and quick debug of complex process issues. Design information is leveraged on the 3900 Series through pin•point™ and super•cell™—patented technologies that improve sensitivity to yield-limiting defects on critical features, including those related to design weak points, and reduce nuisance related to non-critical features, such as dummy patterns. With enhanced imaging and automatic defect classification capability, the eDR7280 e-beam review system quickly delivers an accurate representation of the defect population detected by the broadband plasma inspectors, dramatically reducing the time required for defect discovery.