- Home

- Companies

- Sag Harbor Industries, Inc.

- Products

- Sag-Harbor - Molded Coils

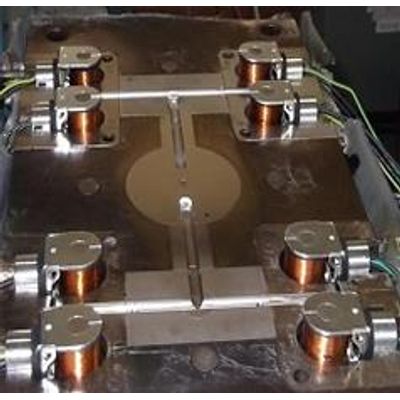

Sag-Harbor - Molded Coils

Molded coils are our specialty. Our multi-faceted molding capability includes eight transfer mold presses and four injection mold presses for both thermoplastics and thermoset materials. Epoxy transfer molding of coils and solenoids is the best protection against harsh environments. We also offer a poured molding process using liquid epoxies or silicone elastomers. From mold design, to prototyping, to high-volume production, we assure high quality and close tolerances for virtually any application. Our molded coils are designed to meet or exceed customer expectations. Sag Harbor Industries employs UL approved class B, F and H insulation systems. We utilize large capacity shuttle presses up to 80 tons as well as multi-cavity molds for the lowest possible cost production of molded coils.

Production Capacities

- A Variety of Molding compounds

- RYNITE

- RE5220

- NYLON 6/6

- SLAC EPOXY

- RYTON

- MH6-XXX

- RTV 8112

- EPOCAP 19284

- EPON EPOXIES

- INSULCAST EPOXIES

Coil Terminations

Coil terminations are a critical path in connecting coils to the outside environment. We offer numerous solutions for terminating coils, below are just some of our capabilities:

- Method

- Dip or Hand Soldered

- Ultrasonic and Fusion Welded

- Potted or Overmolded

- Type

- Terminals, Tabs or Lugs

- Self or Flexible Leads

- PCB Connections

-

- NPT or Conduit Connections

- Welded tabs

Quality Assurances

We place a priority on quality. Our coils are produced in compliance with our ISO 9001:2008 certification. We maintain the absolute highest quality control measures to ensure customer satisfaction. Our self-auditing and inspection techniques are rigorous and thorough. Our team undergoes training and certification programs to ensure expert craftsmanship.

Our ISO 9001:2008 certification gives our customers the confidence that our production facilities, our internal and external auditing methods and our quality control procedures meet or exceed international standards. We consistently rank in our customer’s “Highest Vendor Ratings”. From product conception to application, our goal is to produce the highest quality product; as well as to deliver it on the designated date consistently and to continually improve in every aspect of our business.

Industries Served

- Aerospace

- Military and Naval Sensors

- Automotive

- Control Systems

Value Added Services

Value-added services are available per your requirements:

- JIT/KanBan system options per customer`s preference.

- RoHS compliance at your request

- 24-hour response time when responding to feedback

- The products we make are completely proprietary and never compromised

- Personal and direct service with on-site communication

- Teamwork between us and you, with superior performance being the goal