- Home

- Companies

- DAS Environmental Expert GmbH

- Products

- DAS - Model Salvinia - Moving Bed ...

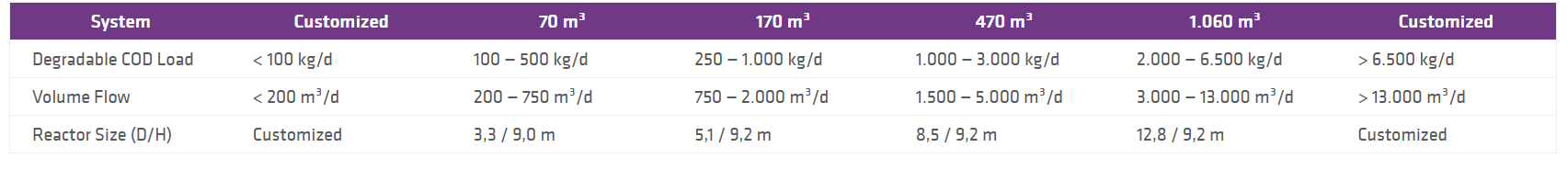

DAS - Model Salvinia -Moving Bed Biofilm Reactor (MBBR)

The MBBR process used in the SALVINIAs is primarily utilized for the degradation of organic wastewater constituents as well as ammonium and nitrate loads. The residual substances produced are carbon dioxide, water, nitrogen and small amounts of biomass.

Our SALVINIAs can be used, for example, as a low-load stage in a single-stage treatment plant with indirect discharge. They are also suitable as the first part of a two-stage plant with direct discharge.

The term SALVINIA, by the way, comes from botany and stands for the genus of floating ferns. Like our wastewater treatment plants, this type of aquatic plant has a particularly purifying effect. This is because they extract excess nutrients from the water and even have an oil-absorbing effect.

The MBBR process is a technology for biological wastewater treatment. In this process, microorganisms are cultivated as a biofilm on carrier material. These microorganisms are responsible for the degradation of both organic wastewater ingredients and nitrogen compounds. As with other biological processes, wastewater treatment with MBBR bioreactors also produces excess sludge. However, the amount is significantly less than in conventional activated sludge processes with similar capacity. Therefore, no recirculation of activated sludge is necessary.

Due to the microorganisms living in biofilms, the MBBR treatment process is also very robust and much more stable than other biological treatment technologies. MBBRs function well even under difficult conditions and recover very quickly after downtimes. This makes them a very resilient solution for industrial wastewater treatment. Whether new construction, expansion, optimization or service & maintenance of an existing wastewater treatment plant. We — the DAS Environmental Experts — take over all tasks as a full service provider.

Standardization brings numerous advantages, especially in the production industry and in mechanical engineering. We would like to transfer these advantages to the field of wastewater treatment with our SALVINIA product group.

- low reactor volumes due to highly efficient carrier material

- a strongly shortened engineering process and thus optimized costs & low time expenditure

- reduced residual material

- fast & uncomplicated performance optimization, for example in case of production increases (without any construction measures)

- robust and stable treatment process, even under difficult conditions

- fast recovery after downtimes

- space-saving container design

- simple cost reductions possible by using existing buildings