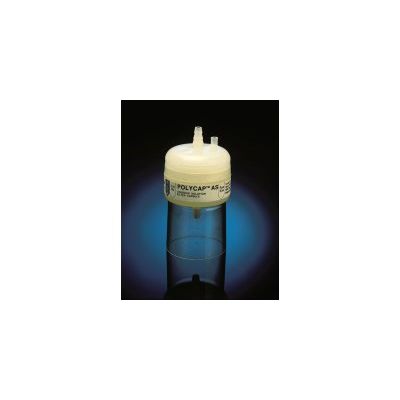

Cytiva Whatman - Model Polycap AS -Nylon Membrane Filter and Glass Microfiber (GMF) Prefilter

Cytiva’s Whatman Polycap AS (Aqueous Solution) combines a nylon membrane filter and glass microfiber (GMF) prefilter for a long lifetime device that can filter large volumes of even difficult, particulate-laden samples.

Cytiva’s Whatman Polycap AS (Aqueous Solution) combines a nylon membrane filter and glass microfiber (GMF) prefilter for a long lifetime device that can filter large volumes of even difficult, particulate-laden samples.

- First layer (GMF) acts as a prefilter to ensure longer membrane (0.2, 0.45, and 1.0 µm) life and higher filtration efficiency.

- Nylon membrane filter layer is inherently hydrophilic, has low extractables, is biosafe, and has excellent flow rates

- Polypropylene housing is thermally fused (no glues, adhesives, or extraneous materials), reducing extractable levels

- Can be tested with bubble point, pressure decay, or forward flow methods

- Available in presterilized and nonsterile (autoclavable) versions

- Manufactured according to ISO9001:2008 QMS standards

Whatman capsule filters from Cytiva Healthcare’s Life Sciences business are available for a variety of applications. Browse the Polycap line to find the filter that matches your needs.

Polycap AS are Whatman capsule filters specifically designed for high-volume filtration of aqueous sample solutions in a compact size. With a nylon membrane filter and GMF prefilter, these filters have a long usable life.

- Housing : Polypropylene (PP)

- Sterile : Yes

- Operating Pressure Max. : 4.1 bar (60 psi)

- Vent : On inlet

- Prefilter : Glass microfiber double laminated with polyolefin monofilament non-woven

- Endotoxin Level : LAL tested, ≤0.5 EU/ml

- Sterilization : Certain filter devices have been sterilized.Capsules may be autoclaved at 121°C for 20 minutes. However, an integrity test should be performed after autoclaving. Filling bell is not autoaclavable but is detachable.

- Sealing : Heat-fused

- Support System : Polypropylene (PP)